Manufacturers started paying close attention to organosilanes in the latter half of the twentieth century, and 3-Aminopropylmethyldimethoxysilane soon earned a pivotal role in materials science. As glass, ceramics, and plastics advanced, chemical companies and university labs hunted for ways to create stronger bonds between organic and inorganic phases. Early trials with aminoalkoxysilanes opened new doors, thanks to their dual functionality. Production scaled up; scientists saw results that outperformed older coupling agents on durability and reliability in harsh environments. Over time, applications grew to include adhesives, sealants, composites, and even electronics, driven by the tireless work of people who refused to accept mediocrity from the materials they relied on every day.

3-Aminopropylmethyldimethoxysilane carries the expertise of chemistry labs into practical fields. The molecule features a methyl group for steric hindrance and an aminopropyl chain for reactivity with organic substrates. Both ends of this compound bring something to the table: the amino group opens doors for further chemical manipulation or cross-linking, while the silicon center, flanked by methoxy groups, hooks onto surfaces like glass or metal. Chemists appreciate how this molecule bridges the gap between two very different worlds—organic polymers and inorganic surfaces—delivering improved mechanical strength and resistance to moisture or heat. In my experience, this product manages complexity behind the scenes, making an everyday process like bonding glass fibers into epoxy resins much more reliable.

Anyone who has worked with 3-Aminopropylmethyldimethoxysilane knows its standout traits. It's a colorless to pale yellow liquid, giving off a sharp, ammonia-like odor. Volatility can turn risky if ventilation lags behind. The boiling point sits around 200°C (at atmospheric pressure), but this doesn’t mean the compound evaporates freely under normal conditions. Density lands near 0.97 g/cm³, and its viscosity allows for simple mixing, but it quickly hydrolyzes when exposed to even small amounts of water, producing methanol and silanols. This reactivity need careful handling—sealed containers, dry environments, and personal protective equipment always come into play. Beyond immediate handling, the functional groups encourage both nucleophilic and electrophilic reactions, showing real versatility for chemical engineers and formulators.

Product labels deliver more than regulatory compliance; they serve as a critical point of communication for end-users. Typical grades of 3-Aminopropylmethyldimethoxysilane sit at a purity no lower than 98%, making them reliable for demanding operations. Containers clearly reference the molecular formula (C6H17NO2Si), molar mass (163.29 g/mol), UN numbers (often UN 2735), and hazard pictograms illustrating flammability, toxicity, and environmental risks. I pay close attention to these sections, since mistakes can lead to costly downtime or more severe personal harm. Labels must also indicate storage guidelines, compatible materials, and what to do in the event of spills. Clear and accurate information on every drum or bottle gives peace of mind, particularly when regulatory inspectors visit or work shifts rotate.

Producing 3-Aminopropylmethyldimethoxysilane calls for careful orchestration. Most facilities begin with methyldimethoxysilane and use an alkylation process—often involving aminopropylchloride and an appropriate base—while maintaining rigorously dry conditions. The product of this synthesis isn’t always perfect, so technicians distill the result under reduced pressure to achieve the required purity. Clean, dry glassware and atmospheric controls prevent unwanted side reactions or polymerization. Staff undertaking this synthesis typically complete thorough hazard assessments, since the byproducts, residual solvents, or even minor impurities can pose risks downstream or limit the final product’s performance. Real-world production lines use in-line sensors, checking for water contamination or temperature spikes, ensuring every batch meets client expectations.

3-Aminopropylmethyldimethoxysilane steps up as a versatile workhorse. The aminopropyl group reacts with epoxy, isocyanate, acid chloride, or even acrylate groups, creating strong covalent bonds in polymer networks. Meanwhile, the methoxysilane groups hydrolyze in wet conditions, forming silanols that condense onto mineral fillers, glass, or metal oxides, creating a durable siloxane bond at the interface. These features let formulators achieve properties impossible by mechanical mixing alone. With proper protocols, the molecule also undergoes modifications: attaching longer alkyl chains, switching out methoxy groups for ethoxy types to optimize reactivity, or introducing fluorescent markers for advanced diagnostics. My own work has revealed how subtle tweaks in molecular structure can have outsized impacts in terms of shelf-life, process temperature, and ultimate product resilience in the field.

Synonyms cause headaches during procurement, so it pays to recognize the key variants. People buying or selling this compound often encounter names like N-(3-(Dimethoxymethylsilyl)propyl)amine, gamma-Aminopropylmethyldimethoxysilane, 3-(Dimethoxymethylsilyl)-1-propylamine, or its shorter version, APMDMS. Proprietary names from vendors like Gelest, Evonik, or Shin-Etsu can overshadow the chemical identity, but smart teams track the CAS number (usually 31024-56-3) and always double-check technical datasheets. Overlooking a synonymous product might seem minor until an order arrives and fails to match a validated formulation—costing both time and trust. It’s always better to reference both registered and common names, keeping miscommunication at bay.

Working with 3-Aminopropylmethyldimethoxysilane requires rigorous adherence to safety. Splash-proof goggles, nitrile gloves, and well-fitted lab coats become second nature. Local exhaust ventilation handles fumes and air monitoring checks for exposure levels, especially since inhaling vapors or accidental skin contact can irritate mucous membranes and, in high doses, affect organ systems. Safety data sheets demand careful reading: users must avoid sources of ignition since the compound’s flammability rises when methanol is released during hydrolysis. Emergency showers and eyewash stations should always remain uncovered, and spill kits must sit close to every workspace. Trained staff learn to segregate wastes, avoid mixing with acids or oxidizing agents, and document every incident, large or small, for future scrutiny. In regulated industries like medical or electronics, audits ensure compliance, reinforcing a culture where safe practices matter more than mere productivity quotas.

Textiles, automotive composites, electronics, and construction all benefit from 3-Aminopropylmethyldimethoxysilane’s unique properties. In my role supporting adhesives development, this silane couples glass fibers with epoxy resins, boosting mechanical properties far beyond those achieved by filler alone. Manufacturers producing printed circuit boards look for consistent dielectric properties and high thermal resistance, both delivered in part by this material’s robust siloxane backbone. Paint chemists enjoy its compatibility with pigments and fillers, improving coating adhesion and weathering resistance. Specialty formulations for sealants or elastomers in automotive gaskets use the compound to fend off corrosion and maintain flexibility under load. Even in niche applications like optoelectronics or biomedical surfaces, tailored modifications of the molecule allow developers to tune biocompatibility, reduce leaching, and extend device lifetimes. Each application pushes product requirements, challenging researchers and product managers to keep learning and adapting.

R&D teams dig into both foundational science and tomorrow’s innovations. Journals fill with fresh insights into how silanes like 3-Aminopropylmethyldimethoxysilane interact with mineral surfaces at the nanoscale, using spectroscopy and atomic force microscopy to map reaction pathways relevant to real-world durability. Research teams at universities and private labs focus on modifying this molecule, seeking ways to extend shelf-life or reduce toxicity while enhancing compatibility with next-generation polymers. Some pursue sustainable synthesis, testing bio-based feedstocks or green chemistry approaches to reduce the environmental footprint. Armed with grant funding or industry partnerships, scientists investigate compatibility with nanofillers, room-temperature curing systems, or recycled aggregates in construction. Regular collaboration between bench chemists and application engineers amplifies these efforts, translating theoretical gains into measurable, market-ready improvements. This spirit of inquiry and relentless improvement drives the field forward and helps industries solve persistent problems.

Data from animal studies, industrial hygiene surveys, and toxicological databases paint a picture of moderate acute toxicity. Inhalation or skin absorption leads to irritation, and some chronic studies indicate possible damage to internal organs at high exposures. Methanol, generated during hydrolysis, adds another layer of risk—well documented for systemic toxicity, particularly affecting the optic nerve and central nervous system. Regulatory bodies across Europe, North America, and Asia classify the compound as hazardous, urging a precautionary approach. Toxicologists and industrial physicians recommend routine monitoring of airborne concentrations, strict adherence to exposure limits, and thorough accident documentation for any incident involving splashes or leaks. Regulatory filings often include animal testing reports, skin sensitization studies, and detailed analysis of hydrolysis products’ health impacts. Companies lean into these findings, continuously upgrading ventilation, training, and medical surveillance.

Industry and academia see a long runway ahead for innovation. Sustainability pressures motivate chemists to develop less hazardous analogs or find greener synthesis methods, such as using bio-based alcohols or reducing solvent usage during production. Additive manufacturing stands out—3-Aminopropylmethyldimethoxysilane opens up stable bonding between new filler systems and polymer matrices, supporting lighter, stronger components for transportation or electronics. Nanotechnology researchers probe the limits of surface modifications enabled by silanes, with implications for battery technology, sensors, and medical diagnostics. Environmental regulators encourage lower toxicity, higher efficiency, and more streamlined labeling, pushing makers to be nimble and transparent. I’ve seen cross-disciplinary teams, drawing on expertise from material science, toxicology, and manufacturing, build safer, smarter products that address durability, recyclability, and energy use all at once. The road ahead demands both respect for fundamentals and a willingness to challenge established best practices, keeping progress grounded in real-world needs and evidence-based decision making.

3-Aminopropylmethyldimethoxysilane looks like a bit of a tongue twister, yet it comes up again and again on technical data sheets and in clean factories. This compound, built around silicon, gives chemists and manufacturers a tool that works across a surprising list of jobs. What I find striking about it is how a small change in the structure of a molecule leads to big shifts in how we treat surfaces and assemble products.

This silane lands in flooring adhesives, protective coatings, and even electronics. In the lab, its main trick comes from both ends of the molecule: one side grabs onto inorganic materials like glass, silica, or metal oxides, while the other has an amine group that bonds well with organic polymers. Put simply, it lets two types of materials—materials that usually stay apart—stick together. As someone who’s worked with glass resin repair, I know frustration from seeing a repair fail because the bond didn’t hold. Silanes like this one solve that problem by creating a strong bridge that resists water and physical stress.

I remember product runs where adhesion just wouldn’t stick, no matter what the factory tried. Sometimes the answer was as simple as adding a silane primer. 3-Aminopropylmethyldimethoxysilane helps not only with adhesion, but also adds some weather resistance. This means paints stay put on buildings, sealants last longer, and circuit boards survive harsh conditions.

In microelectronics, engineers treat tiny silicon wafers with this silane to create layers that interact well with other chemicals. Fiberglass manufacturers also use it as a coupling agent. The fiberglass strands need to connect tightly with the plastic around them, otherwise a finished part turns out weak or brittle. Good silane chemistry sort of acts like a handshake that keeps glass fibers and resin working together, making boats, car body panels, and wind turbine blades safer.

Every time chemicals like 3-Aminopropylmethyldimethoxysilane show up in the workplace, questions follow. Is it safe? What is the impact on the people handling it every day? According to the European Chemicals Agency, this compound can cause irritation to skin and eyes, so gloves and good ventilation matter. Shift supervisors can help by making sure workers get the right protective gear, and by choosing formulations that minimize fumes and waste.

People want adhesives and coatings that work well, last long, and don’t leave behind toxins. The trend in the chemical industry points toward finding silanes that offer the same benefits but lower health risks and environmental impact. Research teams keep tweaking how these molecules break down after use, or how to make them from raw materials that aren't derived from fossil fuels.

I’ve seen companies save money and energy by switching to more dependable coupling agents like 3-Aminopropylmethyldimethoxysilane. For anyone building or fixing things that need surfaces to stay together, not fall apart, it’s clear this tiny molecule solves problems that show up across industries. With careful handling and a push for greener chemistry, it delivers on its promise to build things stronger and safer.

If you’ve spent any time in a chemistry lab or plant, you get to know which chemicals need more respect than others. 3-Aminopropylmethyldimethoxysilane is one of those that call for close attention. Handling this compound in the open or without gear almost always invites trouble. It can irritate the skin, eyes, and lungs faster than you expect, not to mention what it can do if you breathe in the vapors. Taking the right steps before starting work keeps you and your coworkers out of the clinic and on the job.

I learned quickly that lab coats and gloves aren’t optional—your hands will soak up chemicals before you even notice. With this silane, you want more than the thin latex gloves in many dispensers. Nitrile or neoprene offer better protection. I always make sure to wear goggles tight to the face and a face shield when there’s a risk of splash. If the process generates a lot of vapor or involves heating, a proper respirator saves your lungs. Regular safety glasses won’t cut it here.

Years ago, I watched someone open a drum in a room with poor air movement. The odor set off the smoke alarms, showing how vapors spread fast. Using this compound inside fume hoods or with exhaust fans stops those harmful fumes from building up. If ventilation gets ignored, the whole workspace starts to smell like ammonia—never a good sign. Sealing the container right after use and storing it somewhere cool and dry pays off later. I always double-check for leaks and keep it away from water sources, since contact with water can start an exothermic reaction and release methanol.

No matter how careful you are, spills sometimes catch you off guard. I once dropped a small bottle onto concrete, and the chemical spread fast. Absorbent pads and sand helped stop the spill, but the real value was knowing where the emergency showers and eyewash stations stood. Once, someone next to me got splashed and reached the shower in seconds, avoiding a major burn. Knowing evacuation routes and having spill kits handy makes all the difference.

It surprises me on job sites how many people skip the chemical safety data sheets thinking they know enough. Reading the SDS for 3-Aminopropylmethyldimethoxysilane gives you the lowdown on health effects, and the emergency steps if anything goes wrong. Practice emergency drills, so no one freezes in the moment. At every lab where I’ve worked, periodic training makes the routines second nature.

In group settings, clear labeling and concise instructions cut down confusion. It helps to use labels that actually stick and legible handwriting that doesn’t leave anyone guessing. Before a task starts, everyone in the area should know about the risks and safety steps. I’ve found laminated quick guides posted above benches keep reminders fresh in everyone’s mind.

Long shifts and busy labs sometimes tempt folks to cut corners. Over the years, sticking with safety rules—even when no one watched—meant no serious injuries occurred in my teams. Handling chemicals like 3-Aminopropylmethyldimethoxysilane calls for respect each time. Simple steps like checking your gloves for holes or making sure the hood fans run make all the difference between routine work and a medical emergency.

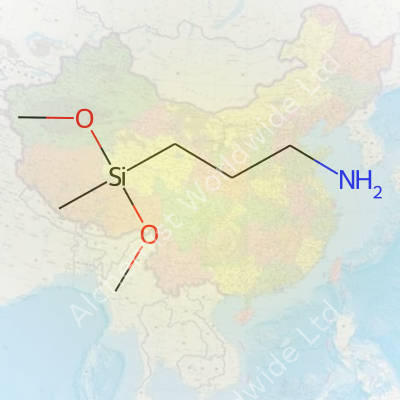

3-Aminopropylmethyldimethoxysilane goes by the formula C6H17NO2Si. I like to picture its structure as a chain with a silicon atom bringing together different groups that each have a specific role. The silicon atom sits at the center, attached to a methyl group, two methoxy groups (–OCH3), and a three-carbon chain ending with an amine (–NH2). Draw it on paper and you see: H2N–(CH2)3–Si(CH3)(OCH3)2. That’s where its unique versatility really starts.

Notice the two methoxy groups. You find them right next to the silicon atom. They act as the gateway for reactivity—it’s what lets this molecule attach to glass, ceramics, metals, or even plastics. These methoxy groups hydrolyze in water, meaning they turn into silanol groups (–Si–OH) very easily. On a real-world level, this translates directly to how well coatings stick, how long paints last, and how durable composites end up after years of wear and tear.

The three-carbon chain acts like a bridge from the silicon anchor to the amine on the other end. That amine group kicks up the ability to bond with other things—especially epoxy resins, polyurethanes, or even biological molecules. In practical terms, you often see this compound used as a coupling agent. When making fiberglass or sticking dissimilar materials together, 3-Aminopropylmethyldimethoxysilane pops up over and over because it creates that crucial link between a rigid, inorganic world and the softer, organic side.

You can see products boasting longer lifespan and more reliable adhesion thanks to silanes like this. It’s especially common in electronics and automotive manufacturing because you want every tiny component to stay put and resist moisture. I’ve handled projects where skipping a coupling agent led to coatings peeling within months. That little switch—adding 3-Aminopropylmethyldimethoxysilane—made the difference between a product failing and meeting a five-year guarantee.

Handling the raw compound comes with some health and safety conversations. The methoxy groups hydrolyze, producing methanol, so ventilation and gloves aren’t just paperwork—they’re real requirements. Some colleagues developed skin reactions from careless handling, so treating it with respect moves from the lab manual right into daily practice.

Researchers hunt for even greener and safer versions, especially as regulations focus on reducing volatile organic compounds. For now, 3-Aminopropylmethyldimethoxysilane still fills a niche that no other molecule quite matches. Some suggest using pre-hydrolyzed blends, which lower vapor release. Others pivot to alternative silanes with less hazardous byproducts. From a sustainability perspective, moving toward waterborne systems and supporting closed-loop processing in manufacturing facilities stand out as steps that actually make a dent in reducing exposures and emissions.

A deeper understanding of both the chemical formula and the structure provides insight not just into how these silanes work, but how using them safely and purposefully improves both products and workplace conditions. Good science walks hand in hand with real care about our environment and health.

Plenty of people underestimate the harm that can show up in a bottle labeled with a complicated name. I spent five years working in a lab that ran daily on small organosilanes. One lesson stood out: chemical storage isn't just about following rules—it's about protecting everyone in the building. Mishandling materials like 3-Aminopropylmethyldimethoxysilane turns a safe workplace into a risky one quickly. Unpleasant surprises like popped seals, white crusty bottles, and fumes can appear overnight.

3-Aminopropylmethyldimethoxysilane gives no second chances around water. Any hint of humidity transforms it. Vapors settle into sticky droplets, containers fuse shut, and—worst of all—siloxane byproducts roll out. If you ever tried opening a bottle that hissed with pressure and crusted threads, you saw those byproducts. Damage doesn't stop with the bottle; they coat shelves, eat into metal, and corrode surfaces. Nobody wants that kind of mess.

Shove this chemical into a spot with a steady environment. Constant temperature makes the biggest difference. A cool room—nothing below freezing, nothing above room temperature—slows down those edge-of-your-seat reactions. Forget lab benches near heat vents or sunny windows. That kind of luck runs out fast. Use tight-fitting caps, no leaky threads, no shortcut stoppers. I’ve seen a single careless swap—rubber for plastic—erase a thousand dollars in a night through contamination.

Dry air is even more important. If your space lacks a desiccator, get silica gel packets. Tuck them close to the bottle. Change them when they darken—you’ll spot the difference, and you’ll keep the silane dry. Store the bottle upright, inside a chemical cabinet meant for organosilanes. Leave flammables and oxidizers elsewhere. Shelving gets sticky if someone combines incompatible goods.

Every label tells a story. Permanent marker labels stay readable. Date every container once it’s open. That detail helped me pinpoint more than one batch with odd odors or strange bugs forming because someone lost track of how long a bottle sat open.

Inventory sheets aren’t busywork; they trace problems before they start. Most chemical spills I’ve cleaned happened because no one checked the logs. A tracking habit means faster freezes of bad lots, recalls, and less risk for the folks doing the grunt work in the lab.

Personal protection counts for everything. Use gloves, goggles, and coats every time the bottle comes out. Vent hoods make sure vapors drift away. Breathing trouble has a way of sneaking up, and working in old buildings with poor ventilation makes the risk climb fast. In my experience, the sharp ammonia notes from poor storage haunt the air, and one good headache stays in memory.

Everyone benefits when the workplace takes chemical storage seriously. Accidents cost more than time—they hurt people and trust. Taking control of chemical storage with proper cabinets, dry air, good tracking, and consistent checks weighs less than the cost of a hospital trip caused by careless habits. The payoff stretches from the bench to the boardroom and out to the neighborhood that never asked for chemical spills on their street.

3-Aminopropylmethyldimethoxysilane—quite a mouthful—often comes up when working with glass, metal, or ceramic surfaces. Anyone who's spent time around composite materials, adhesives, or specialty coatings will tell you: surface treatment counts. The weak link in most things isn’t the main ingredient, but the point where two dissimilar materials meet. Problems there invite peeling, delaminating, or early failure. That’s where this silane coupling agent pulls its weight.

I’ve seen labs use this compound to treat glass fibers, prepping them so that resins actually stick during composite manufacturing. Take a busted carbon-fiber bike frame—if you look at the failure point, it’s often the fiber-resin boundary that lets go. A solid silane layer, applied with care, cuts repair rates and extends product life. This is a result of the silane’s amine group forming bonds with organic polymers, while the methoxysilane end bonds tightly to inorganic surfaces. A little chemistry keeps whole industries running smoother.

Anyone working with circuit boards runs into adhesion headaches. Many silicone-based coatings won’t hang on unless the board gets special treatment. Techs in electronics plants use 3-Aminopropylmethyldimethoxysilane to prime board surfaces before potting or conformal coating. The result: better protection against moisture and dirt, longer product lifespans, and fewer warranty returns. Global output of consumer electronics would suffer plenty more hiccups without chemical links at the micro level holding everything steady.

At the job site or the factory, reliable glues are part of daily life. Manufacturing doesn’t move forward if adhesives don’t do their job. 3-Aminopropylmethyldimethoxysilane often appears in two-part epoxy systems and sealants, often on metals or in construction. Its role: make sure sealants latch onto both sides of a joint. I’ve watched this play out on architectural glass, where strong bonding helps skyscraper windows stand up to wind and weather. Without that silane kick, you can sometimes peel off a sealant layer with your fingers.

Research from multiple journals—including studies from the Journal of Adhesion Science and Technology—backs up the claim: proper surface priming with aminosilane boosts bond strength by double-digit percentages. Even a small uptick makes life easier for the folks responsible for product quality.

Surface coatings make up another big category. Paints that last on metal or glass almost always involve silane agents in their primers. The paint industry has leaned into these additives as environmental standards have tightened. By improving surface bonding, you get away with using fewer harsh chemicals. That approach cuts volatile organic compounds (VOCs) and helps coatings pass stricter regulations. Safety teams in factories, and end users down the line, all benefit when the coatings hang on and hold up.

Handling and disposal of these chemicals still deserves more attention. Many companies are now demanding safer silane manufacturing and tougher environmental tracking for industrial chemicals. Education, ongoing safety testing, and transparency need to keep pace with innovation. Without strong oversight, the benefits can slip into long-term environmental troubles. Responsible use starts with knowing exactly how a material like 3-Aminopropylmethyldimethoxysilane gets used, tracked, and ultimately replaced or recycled down the line.

| Names | |

| Preferred IUPAC name | 3-(Dimethoxy(methyl)silyl)propan-1-amine |

| Other names |

3-Aminopropyldimethoxymethylsilane N-(3-(Dimethoxymethylsilyl)propyl)amine Methyldimethoxy(3-aminopropyl)silane 3-Aminopropyl(methyl)dimethoxysilane |

| Pronunciation | /ˈθriː əˌmiːnoʊ ˈproʊpɪl ˈmɛθəl daɪˌmɛθɒksɪˌsaɪleɪn/ |

| Identifiers | |

| CAS Number | 3663-44-3 |

| 3D model (JSmol) | `3Dmol:'CCNCC[Si](C)(OC)OC'` |

| Beilstein Reference | 1861126 |

| ChEBI | CHEBI:87163 |

| ChEMBL | CHEMBL4551077 |

| ChemSpider | 87361 |

| DrugBank | DB14599 |

| ECHA InfoCard | DTXSID8021745 |

| EC Number | 213-667-5 |

| Gmelin Reference | 69019 |

| KEGG | C14373 |

| MeSH | D000070383 |

| PubChem CID | 123273 |

| RTECS number | UF8586000 |

| UNII | XN1T41ERN0 |

| UN number | UN2735 |

| CompTox Dashboard (EPA) | DTXSID9020704 |

| Properties | |

| Chemical formula | C6H17NO2Si |

| Molar mass | 221.38 g/mol |

| Appearance | Colorless to light yellow transparent liquid |

| Odor | Ammonia-like |

| Density | 0.945 g/mL at 25 °C |

| Solubility in water | soluble |

| log P | 0.1 |

| Vapor pressure | 1 mmHg (25 °C) |

| Acidity (pKa) | 11.3 |

| Basicity (pKb) | 6.7 (pKb) |

| Refractive index (nD) | 1.418 |

| Viscosity | 3-6 cP |

| Dipole moment | 2.51 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 218.6 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -356.7 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -5986.6 kJ/mol |

| Hazards | |

| GHS labelling | GHS02, GHS05, GHS07 |

| Pictograms | GHS05,GHS07 |

| Signal word | Warning |

| Hazard statements | H302, H312, H319, H332, H335 |

| Precautionary statements | P261, P280, P305+P351+P338, P304+P340, P312 |

| NFPA 704 (fire diamond) | 1-1-0 |

| Flash point | 72 °C |

| Autoignition temperature | 275 °C |

| Lethal dose or concentration | LD50 (oral, rat): 2295 mg/kg |

| LD50 (median dose) | LD50 (median dose): Oral rat LD50 = 2413 mg/kg |

| PEL (Permissible) | PEL: Not established |

| REL (Recommended) | 1 ppm |

| Related compounds | |

| Related compounds |

3-Aminopropyltrimethoxysilane 3-Aminopropyltriethoxysilane N-(2-Aminoethyl)-3-aminopropyltrimethoxysilane 3-Aminopropyldiethoxymethylsilane |