Tracing the roots of 3-Chloropropyltrichlorosilane takes you into the mid-20th century, when industrial chemistry started exploring organosilicon compounds for modern manufacturing. Companies racing to develop better plastics and rubbers discovered that organosilicon chemistry gave real improvements, especially in surface treatments and coupling agents. The compound’s popularity picked up as researchers looked for materials that could both bond to glass and other minerals, and also provide a handle for organic transformations. Synthetic efforts at scale arrived by the 1970s, once the need for functionalized silanes in durable coatings and adhesives took off. Nowadays, you’ll find it produced worldwide as an essential tool in surface modification and specialty chemical synthesis.

3-Chloropropyltrichlorosilane, sometimes called CPTCS, doesn’t get the same mainstream attention as some others in the silicone family, but regulars in a lab or plant setting recognize its distinct, pungent odor and aggressive reactivity. It acts as a bridge between organic frameworks and inorganic surfaces such as silica, lending stability and performance to treated materials. Most shipments of the compound come in steel drums or glass bottles sealed against moisture, as hydrolysis creates both hydrochloric acid and problematic siloxane polymers. You’ll see CPTCS mentioned under several product labels, reflecting the shifting priorities of regional supply chains and proprietary branding.

CPTCS appears as a colorless or slightly yellow liquid, boasting a boiling point in the range of 180 to 182°C and a density hovering around 1.32 g/cm³ at room temperature. It bites the nose with a sharp smell due to reactive chlorines. What sets it apart from less reactive silanes is its trifecta of labile chlorine atoms around the silicon, responding instantly when exposed to even a whiff of water. The 3-chloropropyl side-chain attached to silicon makes it valuable in organic synthesis, anchoring all sorts of follow-on modifications.

Producers of CPTCS assure high purity—frequently upwards of 98%—as trace impurities or moisture prompt violent decomposition. Shipping containers get marked with UN numbers and hazard tags signifying corrosivity and environmental risk. Chemical Abstracts Service assigns CPTCS the number CAS 10025-78-2, and the compound often appears on safety data sheets with signal words like “Danger” in multiple languages. Shelf life depends on storage—dry, cool, inert conditions keep the product stable for years, but the tiniest crack in a seal brings rapid breakdown.

The industrial route to CPTCS usually starts with allyl chloride and silicon tetrachloride, driven by the hunger for scalability and low cost. Chemists react these in the presence of catalytic initiators or UV light, producing the desired blend of chlorinated alkylsilanes. Post-reaction purification removes by-products like dichlorosilane derivatives. Any water in the process, even vapor, eats away at yield, making inert atmospheres and scrupulously dry glassware routine. Small-batch or research settings sometimes swap in different starting materials to tailor the purity or tune the alkyl chain, expecting minor trade-offs in overall efficiency.

This compound reacts briskly with nucleophiles—think water, alcohols, or amines—liberating hydrochloric acid and tacking new groups onto the silicon. Its 3-chloropropyl arm stays flexible for extra functionalization: forming new C-N or C-O bonds, grafting onto surfaces, or bridging organic polymers to mineral fillers. In silanization, CPTCS can grip strongly to glass fibers, then anchor other agents or catalysts, improving the toughness of composites. Industrial chemists appreciate its bifunctional nature, letting them add silane-protected intermediates into more complicated manufacturing steps.

3-Chloropropyltrichlorosilane stays recognizable, but product lists may also call it by trade names, company-specific abbreviations, or alternative chemical names such as 3-chloropropyltrichlorosilane, trichlorosilylchloropropane, or simply CPTCS. Regional suppliers sometimes stress names highlighting purity, like “High-Purity Chloropropyltrichlorosilane,” underlining strict quality controls that customers demand for advanced technology applications.

Working with CPTCS means putting safety front and center. Skin burns and eye damage arrive fast with direct contact, and the fumes corrode respiratory linings. Good labs lock bottles in dry inert cabinets and require gloves, face shields, and chemical-resistant aprons. Spill kits and eye wash stations sit within arm’s reach. On the plant floor, vented hoods and positive-pressure suits come into play. Strict transport rules apply—vehicles carry spill readiness equipment, and local authorities get notified before any bulk shipment. Chronic exposure data remains sparse, prompting labs to lean on conservative handling precautions. Regulatory bodies place CPTCS in lists of substances requiring risk assessment and environmental monitoring, especially where accidental releases might reach water systems.

CPTCS holds value in a surprisingly broad set of industries. In the production of specialty rubbers, it attaches to mineral fillers, enabling better mechanical properties and long-term stability. Manufacturers working on fiber optics or advanced glass coatings rely on CPTCS for functionalizing surfaces, leading to stronger adhesion between organic coatings and silica-based materials. Electronics companies use it to prep surfaces before mounting silicone-based adhesives or encapsulants, crucial for microchip protection. This compound even finds a home in chemical synthesis, where its reactivity supports complex drug intermediates and custom reagents. Water repellency treatments for concrete, textile finishing, and even certain high-performance lubricants trace some of their performance back to the presence of functional silanes like CPTCS.

Academic chemistry continues to chase better ways to unlock CPTCS’s reactivity. Surface science labs publish new protocols for depositing functional layers on glass and metal oxides, often aiming for medical or environmental sensors. Industrial R&D focuses on cleaner, more selective functionalization—trying to swap only one or two chlorides on silicon without triggering runaway polymerization or side reactions. As green chemistry principles gain traction, ongoing experiments probe less hazardous syntheses, alternative solvents, and improved recovery of waste streams. Collaboration across borders helps scientists uncover new roles for CPTCS in battery technology, advanced filtration materials, and even antimicrobial surfaces.

Toxicologists study CPTCS carefully, as hydrolysis products turn into hydrochloric acid and silanols, both potent irritants. Animal studies show tissue damage at relatively low exposure levels, and accidental inhalation in industrial accidents has led to severe lung injury. Long-term effects remain poorly tracked, making workers’ health monitoring a top priority for safety officers. Environmental impact studies caution against any disposal in waste streams, noting the persistence of chlorinated by-products and threats to aquatic organisms. Advances in analytical testing allow companies to check for trace contamination in finished products, tightening controls on consumer goods using treated glass or polymers.

Looking ahead, demand for advanced composite materials, specialty adhesives, and low-defect semiconductor processing creates ongoing opportunities for CPTCS and its derivatives. Regulatory agencies worldwide ask for greener production and cleaner end-of-life strategies, nudging manufacturers toward circular recycling and solvent recovery. Start-ups continue to explore CPTCS as a launching point for new functional polymers and biodegradable coatings. Improvements in personal protective equipment and remote handling systems lower risk, easing the path for researchers testing the next generation of silicon-based interfaces. As new end-uses emerge—electronic skins, wearable sensors, hydrophobic coatings—expect to see CPTCS remain a staple of innovative material chemistry, drawing on both its adaptable structure and well-understood performance profile.

Silicone sealants around your bathtub or the tough coatings on electrical cables aren’t magic—they’re chemistry in action. 3-Chloropropyltrichlorosilane works as a silent helper behind these applications. For years, I watched construction projects and wondered how certain materials held up so well in harsh conditions. Turns out, it links back to chemicals like this one that help create strong bonds between surfaces that would otherwise refuse to stick together.

In factories building advanced electronics, engineers reach for 3-chloropropyltrichlorosilane to act as a coupling agent. It’s there to help something inorganic, like glass or metal, hold onto organic layers tightly. This bond means circuit boards resist heat, humidity, and rough handling. A poorly-bonded board fails fast, which can wreck whole production lines and waste valuable resources. Research from the American Chemical Society points out that surface treatments using these chemicals reduce microfracture rates in semiconductor delivery by up to 20%.

If you’ve ever noticed how some plastics and rubbers seem flexible but oddly strong, this crosslinking process plays a role. A colleague in automotive part design told me they turn to organosilanes such as 3-chloropropyltrichlorosilane so rubber seals in engines don’t decay too fast. They don’t just last longer but also resist leaking even after thousands of miles on the road. The car industry relies on these bonds, as rubber and silicone without the right additives grow brittle and crack in months.

This chemical’s ability to anchor coatings comes with environmental and safety trade-offs. The chemical reacts strongly with water, so a spill means hydrochloric acid fumes rise almost immediately. Workers need specialized gloves and fume hoods—anyone treating surfaces forgets this at their own risk. I remember visiting a plant where just a splash on an unprotected table started corroding the surface in minutes. Regulatory bodies like OSHA have stepped up to create strict guidelines for handling chemicals like these, requiring full face shields and routine air testing. Failure to follow these leads to health problems, which remain a known issue in smaller workshops with less oversight.

Many manufacturers now seek safer silane alternatives or invest in closed system equipment to reduce worker exposure. This push grows every year, especially across the EU, due to pressure from workplace safety groups and rising insurance costs. If more investment goes into training and advanced protective gear, workplace incidents keep falling. Some companies swap to water-based coupling agents for lower exposure risk, but this shift doesn’t fit every process yet.

3-Chloropropyltrichlorosilane won’t make the news often, but it keeps key industries running. From building safer electronics to reinforcing the seals that keep our vehicles running longer, its impact reaches further than most realize. Safer manufacturing and handling conditions could make the benefits of this chemistry accessible without undue risk to workers and the environment.

3-Chloropropyltrichlorosilane isn’t just another chemical on the shelf. Its sharp, choking odor and strong reactivity hint at the risks within the bottle. A friend once told me about a splash that burned right through his gloves, showing just how fast this stuff goes through the usual protection. It reacts quickly with water and air moisture, forming corrosive hydrochloric acid and silanols, so any mishap multiplies health and environmental hazards fast.

Chemical leaks and reactions often come down to storage mistakes. Years working in labs taught me that keeping a substance like 3-chloropropyltrichlorosilane in just any cabinet would be flirting with disaster. This compound eats through lots of common packaging. There’s no shortcut: glass bottles sealed with PTFE-lined caps, not regular plastics or metals, hold up. Strong ventilation in storage rooms makes sense because fumes escape even with good packaging.

Heat and sunlight push up internal pressure and speed up decomposition. Direct sunlight turns the safest container into a bomb waiting to burst. Keep it in a cool, dry spot, away from windows, outside walls, and steam pipes. Rooms used for these chemicals usually have spill containment—think trays or bunds—under every shelf so even if a bottle leaks, the mess stays put. Store away from water, alcohols, bases, and anything that could trigger a violent reaction.

Folks sometimes treat personal protective equipment as a nuisance—until a drop of this liquid burns right through a nitrile glove or produces a cloud of acid smoke that stings every inch of bare skin. Strong acid-resistant gloves, face shields, and long sleeves aren’t recommendations; they’re the only thing standing between someone and a hospital visit.

Handling this chemical means working inside a fume hood. Standard exhaust fans don't catch fast-reacting vapors and corrosion. A good fume hood pulls fumes away and scrubs them before returning air inside the building. Consider a lab coat that resists acids. Eye washes and emergency showers aren’t just boxes to tick on a checklist—they’re lifesavers when seconds count.

Spills turn risky when people scramble or don’t know what to do. Sweep or absorb small leaks with inert materials like vermiculite; don’t use sawdust. Have neutralizing agents close by, like sodium carbonate, so hydrochloric acid gets neutralized before hurting people or equipment.

Every place that keeps 3-chloropropyltrichlorosilane on hand should run real-world spill drills. Any hesitation or confusion invites injury. Make sure updated safety data sheets are on the wall and folks know exactly who to call if anything goes wrong. Fire extinguishers—old-school dry chemical, not water or foam—should be close. This chemical reacts violently with water, so pouring water on a fire only makes things worse.

Until people take chemical hazards personally, there’s always a risk. Mandated training gives basics, but seeing what happens when 3-chloropropyltrichlorosilane hits a puddle sinks the lesson in. Stories from workers who got burned or made mistakes remind everyone that safety isn’t extra—it’s part of the job. A lab or warehouse that laughs off caution invites real harm, so building a culture that respects these substances keeps folks coming home in one piece.

Walking into any industrial site that handles chemicals like 3-chloropropyltrichlorosilane, the air feels different. Maybe it’s just a subtle tingle in the nose or a scratchiness at the back of the throat, but I always notice it, and so do workers who spend time near these kinds of substances. 3-chloropropyltrichlorosilane plays a significant role in the silicone supply chain, but it also brings a set of risks that nobody can afford to ignore.

If someone splashes this compound on bare skin, there’s no gentle warning. Rashes, burns, and blisters show up fast. Even worse, breathing in its vapors irritates the eyes, nose, throat, and lungs. Chemical burns from this silane can develop within minutes. As someone who’s visited sites where safety measures aren’t top-notch, I’ve seen workers rushed to the rinse station after a single stray splash. The U.S. National Library of Medicine highlights that it is corrosive and reacts violently with water. Breathing in even a little can result in coughing or difficulty breathing, and higher exposures lead to real risk for pulmonary edema. Long-term impacts aren’t well-documented, but many chemicals with similar properties have shown chronic effects on the liver, kidneys, or respiratory system after months of exposure.

Most 3-chloropropyltrichlorosilane travels in sealed drums, but spills have happened. A 2016 transport accident in Germany led to a chemical cloud—emergency crews evacuated the area and local wildlife died off quickly in the days that followed. Water doesn’t dilute it safely; the compound violently releases hydrochloric acid and siloxane byproducts instead. Runoff from an accidental release can damage rivers and soil for years. Researchers at the European Chemicals Agency point out the compound’s long persistence in soil and groundwater. Once it’s out in the open, it clings to organic matter and resists breakdown that other organic chemicals would undergo. Fish kills in contaminated streams often trace back to accidental silane releases.

Every industrial user should focus on prevention, not just clean-up. Sealed handling systems, local exhaust ventilation, and full-face respirators help keep workers safer. On the environmental front, investing in spill containment—like double-walled tanks or specialized catch basins—makes a big difference. Even smaller chemical users can prepare with neutralizing agents and proper safety drills. Training must go deeper than a quick video and quiz; people need to know how to spot a leak, how to act fast, and when to call for help.

Pushing for greener materials often gets blocked by cost or performance demands, but innovation shouldn’t stall here. Silicone and silane manufacturers need stronger incentives to research less hazardous options. Collaborations between universities and industry could speed up this process—similar efforts reduced trichloroethylene use in electronics in the ‘90s without driving costs through the roof.

Communities near chemical factories want more transparency. Real-time air and water quality data, easier-to-read hazard labels, and emergency contact numbers on storage tanks should be non-negotiable. Open conversations about chemical use—especially when they involve hazards like 3-chloropropyltrichlorosilane—build trust. Regulatory agencies monitoring these sites should enforce public reporting and accountability.

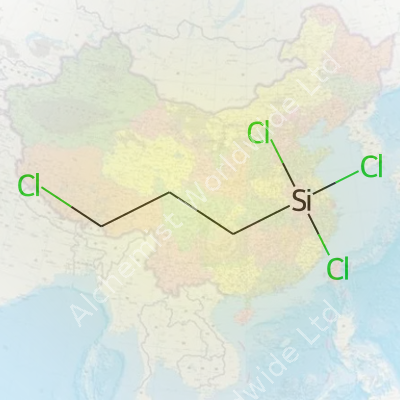

3-Chloropropyltrichlorosilane carries the chemical formula C3H6Cl4Si. Its molecular weight stands at 217.98 grams per mole. These aren’t just dull textbook figures; they set the stage for how this compound influences manufacturing and daily life. A solid grasp of such details paves the way for safe handling and responsible use, whether in a lab or an industrial plant.

Anyone working in chemical industries will probably come across 3-chloropropyltrichlorosilane. I once worked in a facility where people wore layers of personal protective equipment, and safety briefings always circled back to organosilanes like this one. The reason is simple: these chemicals stand out for their ability to react with moisture and with surfaces, shaping what ends up on glassware, electronics, and even medical devices.

This compound helps add functional groups to surfaces — say, prepping silica for use in chromatography or creating links between organic polymers and inorganic substrates. These tweaks bring out unique qualities in plastics and adhesives, bridging gaps between the rigid world of minerals and the flexible world of carbon-based chains.

Working with 3-chloropropyltrichlorosilane also highlights just how much thoughtful planning goes into chemical engineering. If you’ve ever spilled even a drop in a moist space, the hissing and white fumes make it obvious: this stuff reacts strongly with water, boiling off hydrogen chloride gas. That means real, immediate risks to air quality and human health if things go sideways. It stings the eyes, nose, throat, and lungs. Many a chemist has learned this the hard way, discovering that even rotated fume hood sashes can be the difference between a mild cough and a rush to the eyewash station.

Regulatory agencies such as OSHA and the European Chemicals Agency have set strict exposure limits. Detailed data sheets and training help keep incidents to a minimum. Emergency showers, careful label checks, and strict transport protocols show that handling is never done on autopilot.

Labs and factories improve outcomes by pairing engineering controls with robust training. Installing proper ventilation goes a long way. Spending extra minutes rehearsing spill protocols before the workday saves much more time and worry down the road. Some places even install scrubber systems to keep air clean.

On a broader scale, substitutes with lower toxicity can be explored, though switching isn’t always simple. The versatility of silicon-chlorine bonds means many roles can’t easily shift to less reactive alternatives. Responsible purchasing, waste management, and responsible recycling of contaminated gear play central roles in sustainable use.

Industry and academia both step up to provide real-world data and case studies. Businesses often set up partnerships with academic labs to share insights on safer processes and environmental controls. From my own work experience, I’ve seen the impact of these collaborations: fewer accidents, better morale, and a real sense that science can solve its own messes. Chemistry shapes our world, so practical, grounded action becomes everyone’s job.

Working with 3-Chloropropyltrichlorosilane brings some heavy responsibility, if only because of what this chemical can do when handled without care. It isn’t one of those benign solvents you can just flush down the drain or pour on the ground. Anyone who’s opened a container gets a whiff of that harsh, biting smell and feels the sting at the back of the nose—reminding you it reacts quickly with water and forms corrosive and hazardous byproducts like hydrochloric acid. Even small spills can throw off toxic fumes, causing chemical burns to skin, eyes, and lungs. Those of us who have spent time around research labs or chemical plants don’t forget how easily a little carelessness grows into a bigger mess.

Disposal isn’t just about keeping a lab tidy or staying within regulations; it’s about real health and real damage to the environment. Dumping this stuff—no matter how diluted—means hydrochloric acid and organosilicon fragments find their way into water or soil. In some settings, that’s a recipe for releasing fumes and causing long-term harm to both people and wildlife. The EPA and OSHA have laid out clear standards; ignoring them isn’t just risky, it’s personal. Those who cut corners in the short term usually end up with headaches that last years, and communities pay the price.

Lab routines instill respect for materials like 3-Chloropropyltrichlorosilane early. No one working with it should be guessing: goggles on, gloves up, fume hood sash down. Waste accumulates fast, so a clear, labeled waste bottle—made of glass, sealed tightly—stays close at hand. I remember one supervisor telling us, more than once, “Don’t mix your silanes with acid waste. It gets ugly, fast.” That’s not just a warning for beginners. Mixing with even small traces of water can bring on a rapid reaction, clouding up the bottle and releasing heat.

Companies with strong safety cultures hire trained chemists who don’t just hope the maintenance crew “figures it out.” A solid disposal routine means handing the waste off to a team certified for hazardous material transport. They show up with the right paperwork, containers, and know-how. Once the waste leaves the lab, it heads to a chemical disposal facility—sometimes incinerators designed for chlorinated organics, sometimes facilities that neutralize it. Records get logged and signatures collected because the chemical’s journey stays visible every step of the way.

Smaller outfits, like private research groups or startups, often lack in-house expertise for safe disposal. That’s a recipe for workers taking shortcuts—improper labeling, incomplete neutralization, or storing dangerous leftovers in the wrong place. Open communication matters; I’ve seen teams avoid disaster just by sharing what they’re working on and flagging unsafe habits quickly.

Wider access to disposal information would help, too. Clear, straightforward safety training—written in plain English, not just regulation-speak—would lower the hurdles for anyone handling or disposing of chemicals like this one. Vendors who sell such materials could include robust, easy-to-read disposal guidance with every shipment. Regulators already mandate safety data sheets, but making them simpler and more direct would move things in the right direction.

Disposing of 3-Chloropropyltrichlorosilane isn’t a chore you can fake and forget about. Clear protocols, honest teamwork, and access to professional disposal services build a culture that keeps workers and communities safe. Skipping steps—out of ignorance, laziness, or saving a buck—ends up hurting everyone down the line. In this business, respect for the process is what keeps people out of trouble.

| Names | |

| Preferred IUPAC name | Trichloro(3-chloropropyl)silane |

| Other names |

Trichloro(3-chloropropyl)silane 3-Chloropropyltrichlorosilane Silane, trichloro(3-chloropropyl)- 3-Chloropropyltrichlorsilan Trichloro(3-chloropropyl)silane |

| Pronunciation | /ˈθriː-klɔːroʊ-ˈproʊpɪl-traɪˈklɔːroʊˌsɪleɪn/ |

| Identifiers | |

| CAS Number | 13537-28-7 |

| 3D model (JSmol) | `3D6V` |

| Beilstein Reference | 1209282 |

| ChEBI | CHEBI:87363 |

| ChEMBL | CHEMBL518234 |

| ChemSpider | 24221 |

| DrugBank | DB16056 |

| ECHA InfoCard | 03c1914c-c7f2-41ca-9f44-8d680a281383 |

| EC Number | 217-161-3 |

| Gmelin Reference | 148622 |

| KEGG | C18606 |

| MeSH | D017239 |

| PubChem CID | 24856421 |

| RTECS number | TP4550000 |

| UNII | V5D2O31UYO |

| UN number | UN2548 |

| Properties | |

| Chemical formula | C3H6Cl4Si |

| Molar mass | 220.40 g/mol |

| Appearance | Colorless to light yellow transparent liquid |

| Odor | Pungent |

| Density | 1.324 g/mL at 25 °C |

| Solubility in water | Reacts violently |

| log P | 2.9 |

| Vapor pressure | 0.9 hPa (20 °C) |

| Acidity (pKa) | 1.7 |

| Magnetic susceptibility (χ) | Magnetic susceptibility (χ): -7.2e-6 |

| Refractive index (nD) | 1.4500 |

| Viscosity | 3 cP (25°C) |

| Dipole moment | 1.73 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 386.8 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -584.7 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -1732 kJ/mol |

| Hazards | |

| GHS labelling | GHS02, GHS05, GHS06 |

| Pictograms | GHS05,GHS06 |

| Signal word | Danger |

| Hazard statements | H314, H331, H302, H335 |

| Precautionary statements | P210, P220, P260, P261, P264, P271, P280, P301+P330+P331, P303+P361+P353, P304+P340, P305+P351+P338, P310, P321, P363, P370+P378, P403+P233, P405, P501 |

| NFPA 704 (fire diamond) | 3-1-2-W |

| Flash point | 82 °C (180 °F) - closed cup |

| LD50 (median dose) | LD50 (median dose): Oral rat LD50: 1100 mg/kg |

| NIOSH | RN0692500 |

| PEL (Permissible) | PEL (Permissible Exposure Limit) for 3-Chloropropyltrichlorosilane: "No OSHA PEL established |

| IDLH (Immediate danger) | 50 ppm |

| Related compounds | |

| Related compounds |

Chloropropylsilane Propyltrichlorosilane 3-Chloropropyltriethoxysilane Trimethylchlorosilane Methyltrichlorosilane Octyltrichlorosilane Vinyltrichlorosilane |