Chloromethyl(methyl)dimethoxysilane came about during the late stages of the chemical boom in the mid-20th century, as researchers looked for better ways to build advanced materials and coatings. Silicone chemistry had already transformed industries by the 1940s, but practical silane derivatives still lacked versatility. Chemists wanted functional groups on silanes for new polymerizations and surface treatments. Out of this demand, versatile intermediates like this one were created. In those early days, laboratory setups were crude by modern standards, and safety wasn’t the priority it is today. Formulating this compound often meant dealing with hydrochloric acid byproducts and the ever-present risks linked to alkylating agents. Over time, better tools, closed systems, and regulatory pressures shaped safer, more scalable manufacture of these reactive organosilanes.

Few chemicals punch above their molecular weight like chloromethyl(methyl)dimethoxysilane. This clear, colorless liquid operates as a building block, not a showy end product. It rarely gets mentioned outside R&D labs or plant procurement lists, but its impact shows up in water repellency for coatings, improved adhesion in sealants, and molecular linkages in specialty resins. The molecule’s structure makes it a handy crosslinker and coupling agent, driving its adoption in advanced composites and surface treatments. With that reactivity comes caution, as it combines the hazards of both organosilicon chemistry and alkyl chlorides.

This compound delivers as a relatively low-viscosity, low-boiling liquid, typically hovering around 50–55 degrees Celsius for boiling point. Vapor pressure runs higher than many silicone analogues, reflecting its size and structure. Water solubility stays minimal, yet it reacts quickly with moisture, splitting into hydrochloric acid and silanol derivatives. That hydrolytic instability, paired with a strong, biting odor, reminds handlers to treat every drop with respect. Flammability and corrosivity add to the list of risks that anyone in a processing plant learns to manage firsthand. Tools and gaskets see faster wear and tear near this chemical — another problem for anyone responsible for the bottom line.

Companies list purity requirements that usually hit 98% or higher, with tight controls on water content, color, and free acid. Storage and transit labeling must flag corrosivity, toxicity, and the risk of hydrolysis producing dangerous fumes. For international shipments, proper GHS labeling and paperwork follow every drum. From a purchasing standpoint, batch consistency matters most — a sliver of off-spec product renders the end result unreliable, whether in electronics coating or composite bonding. Engineering teams, especially in high-stakes industries, rely on certificate-of-analysis sheets for every shipment. Take it from someone who’s spent too many hours double-checking paperwork and sample vials: trace impurities or label errors get costly, fast.

Manufacturers typically prepare chloromethyl(methyl)dimethoxysilane from methyltrichlorosilane using a methoxylation process, often in the presence of a base and methylating agent like chloromethyl methyl ether. Such reactions bring together strengths and headaches: yields stay high when the input purity lines up, but side-reactions and byproduct formation demand careful control. Process engineers monitor temperature, reagent ratios, and agitation — small deviations make for problematic waste streams or lower purity. Handling chlorinated methoxy reagents draws plenty of regulatory oversight, and plant upgrades often get driven by tightening environmental requirements. Having spent time in small-batch facilities and scale-up operations, I’ve seen the shift from open-vessel syntheses to fully enclosed, evacuated lines, where every flange and valve represents a safety decision.

This silane dramatizes just how reactive small-molecule silicon compounds can be. It undergoes hydrolysis on contact with water or moisture, releasing methanol and hydrochloric acid alongside silanol intermediates. Its alkyl chloride group reacts with nucleophiles, allowing chemists to tack the silane fragment onto organic skeletons or polymer backbones. In both academic and industrial labs, people use it for controlled modifications during polymer manufacture or when they want to anchor silicon onto another substrate. Once, working alongside polymer scientists, I watched it boost cross-link density in adhesives, which led to dramatic improvements in moisture resistance. Every change starts with careful addition: one slip can let in water vapor, setting off an exothermic chain of reactions or splashing corrosive acid — hard lessons for anyone new to bench chemistry.

No one researching specialty chemicals expects a simple name. Chloromethyl(methyl)dimethoxysilane pops up as (Chloromethyl)methyl-bis(methoxy)silane, chloromethylmethyldimethoxysilane, and through supplier codes that reference its structure, like CMMDMS. Catalogs write its CAS number in bold, making it easy for buyers to verify they aren’t getting a near-miss or contaminant-laden analog. Distributors often attach house brands atop IUPAC names, creating confusion for those new to procurement. More than once, a project delay can be traced to someone ordering a similar-sounding silane, and the results range from minor hassle to major process hiccups. Molecular formulas often help clear things up: C5H13ClO2Si says it all.

Safety practices have evolved as industry realized the dangers lurking in every liter of chloromethyl(methyl)dimethoxysilane. Exposure can corrode tissue, assault airways, and leave lingering headaches or worse. The molecule forms hydrochloric acid in situ — a fact that more than a few plant workers have learned with a singed nostril or two. Modern facilities must supply full-face respirators, heavy chemical-resistant gloves, and well-ventilated hoods for every transfer. I remember seeing spills eat through steel, leaving white etching on surfaces and a haze in the air. Waste streams require careful neutralization, and every batch record logs incidents and exposure times for worker safety. Regulations in North America and Europe pushed industry to move from open vessels and flexible tubing to fixed, hard-piped systems with backup containment. No one wants to revisit the days of ersatz protection and cut corners.

Commercial and research labs lean on chloromethyl(methyl)dimethoxysilane for its ability to craft stronger, chemically bonded structures. Specialty coatings use it to repel moisture, adhesives lock it in for stronger bonding, and polymer engineers covet it for building water-resistant composites. In electronics and aerospace, this silane shapes interfaces between glass fibers and resin, translating to tougher end products that stand up to weather, fatigue, and chemical attack. Some surface modification scientists use it to create self-assembled monolayers on silicon wafers, while others value its role in chemical vapor deposition routes. Speaking with colleagues at tech expos, I’ve heard many lament the cost but admit defeat without this particular reactivity — a testament to its value despite the handling headaches.

Academic chemistry programs chase new uses for silanes, and this compound sits at the crossroads of organofunctional reactivity and silicon’s flexibility. Work continues in tuning the functional group for targeted surface binding, which finds its way into everything from drug delivery vehicles to specialty sensors. University teams and commercial R&D labs probe ways to attach the silane to novel substrates, increasing durability or adding new properties such as anti-fouling or biocompatibility. On the industrial end, process scientists keep tweaking reaction conditions for higher purity and lower cost, all in a bid to snag a competitive edge. My own years spent collaborating across chemistry and engineering taught me that no single formulation or modification stays best for long — as soon as a better route arises, the industry jumps.

Much of the talk around chloromethyl(methyl)dimethoxysilane centers on risk. Inhalation, skin contact, or ingestion all pose significant harm, with symptoms from irritation to severe lung damage. Chronic exposure — say, from lax containment or improper PPE — can cause lingering respiratory distress and other health complications due to both the base chemical and its acid derivatives. Animal studies highlight acute toxicity at low concentrations, while workplace standards treat it with the seriousness it deserves: threshold limits stay low, and routine monitoring keeps workers safe. Environmental concerns have grown too, given potential for acid-laden runoff or accidental vapor release. Working with regulatory teams in the past, I saw how documentation, incident tracking, and engineered controls turn from bureaucratic tasks into lifesaving tools.

The path ahead for chloromethyl(methyl)dimethoxysilane will reflect both promise and new scrutiny. Next-generation composites will likely keep demanding its unique combination of properties for building extreme moisture barriers and chemically bonded materials. There’s momentum behind reducing toxicity through better encapsulation, new delivery formats, and greener synthetic routes. I’ve noticed more start-ups exploring safer analogs, yet none match every niche this compound fills. Regulatory agencies steadily tighten oversight, pushing continuous improvement in production and handling. Research communities chase bio-based alternatives and less hazardous processing methods, but the sheer utility of this compound assures it a place in the toolkit of chemists and materials scientists for years to come.

People who spend time in labs, whether for big research or small experiments, run into long, complicated chemical names all the time. Chloromethyl(methyl)dimethoxysilane might sound intimidating, but it tells a real story about structure. Each part of the name points straight to what’s connected to what in the molecule. You see – silane forms the backbone, and the different substituents create unique possibilities for industry work.

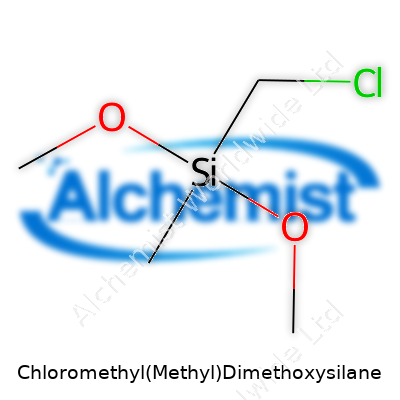

The chemical formula for Chloromethyl(methyl)dimethoxysilane comes down to its building blocks: one silicon atom, a methyl group (CH3), a chloromethyl group (CH2Cl), and two methoxy groups (OCH3). Piece those groups together, and you get C5H13ClO2Si.

This compound doesn’t show up in the headlines, but behind the scenes, it proves useful in many applications. I remember seeing silane derivatives in projects focused on surface treatments and specialty polymers.

With chloromethyl and methyl groups attached to silicon, the molecule brings reactivity and flexibility. Two methoxy groups give it the ability to bond with surfaces or participate in crosslinking reactions. Add a chloromethyl, and the compound can react aggressively with nucleophiles, letting synthetic chemists attach it to other organic frameworks.

These traits matter for everything from the adhesives in electronics to the surface coatings that keep glass from fogging up. That versatility means it draws attention from researchers and product engineers alike. Yet, with its reactivity comes the need for respect — the compound’s chlorine content and ease of hydrolysis mean it calls for good lab practice and reliable ventilation.

I spent plenty of time handling reagents like this. Improper storage or casual handling resulted in headaches and ruined samples more than once. The simple fact is, chlorosilane compounds react with water to form hydrochloric acid and alcohols. That reaction creates corrosive vapor and demands eye protection, gloves, and chemical hoods. Even those with years of experience find themselves double-checking labels to avoid confusion between similar silane bottles.

Safety doesn’t end at the lab door. Anyone introducing these compounds into a product — be it electronics, building materials, or fine chemicals — needs to be aware of regulatory rules from agencies like OSHA, EPA, and the equivalent bodies abroad. Responsible sourcing also comes into play. Reliable records trace from the raw materials through to finished products, minimizing contamination, and improving transparency in the supply chain.

Changes in formulation and new alternative reagents offer hope for reducing problematic byproducts. Green chemistry approaches experiment with different functional groups and less hazardous derivatives. Open discussion between chemists, safety professionals, and managers always brings better practices. Training remains a powerful tool — bad habits get weeded out when everyone in the lab understands both risks and the molecule’s practical value.

Sharing this knowledge goes beyond formulas on paper. It’s about real-world application, making work safer, greener, and more reliable. Silane chemistry continues to evolve, but it all starts with knowing what you’re working with — and treating it with the respect it deserves.

Chloromethyl(methyl)dimethoxysilane shapes the way materials interact with the world. Take a close look at modern electronics or protective glass coatings; behind their performance sits hard-earned research and formulations using silane compounds. This one often stands out for the simple reason that its chemical group opens doors to building stronger bonds between organic and inorganic surfaces.

Working in a lab, many folks run into this silane when trying to graft organic molecules onto glass or silicon. The reason traces back to its dual personality. On one end, it latches onto mineral surfaces like a rock climber grabs a hold; on the other, it reaches out to organic groups or polymers. This “bridge” means engineers can transform a brittle glass slide into a water-repellent, fingerprint-resistant surface simply by treating it with a solution containing this compound.

Microchip manufacturers focus on controlling contamination and building thin, robust layers on silicon. Chloromethyl(methyl)dimethoxysilane delivers value because it reacts quickly and sticks where it’s needed—forming a reliable base for building up those delicate and critical semiconductor devices. This method cuts down errors and improves yields. Making errors less likely in the cleanroom means higher quality chips for the phones, computers, and communication infrastructure most folks count on daily.

Surface-treating chemicals like this one are not some distant idea—they end up in the things we hold or carry every day. Smartphone displays offer clearer pictures and wipe clean with less effort after being coated with thin, invisible layers derived from silanes. Lenses, solar panels, and architectural glass also use water-repellent coatings born from reactions involving chloromethyl(methyl)dimethoxysilane. Rather than just reducing smudges, these treatments extend product life and mean less elbow grease scrubbing away grime.

Researchers in bioengineering often look to silanes to make glass, quartz, or silicon surfaces behave differently—maybe more attractive for binding proteins or repelling certain chemicals. In medical diagnostics, for example, tuning a surface using chloromethyl(methyl)dimethoxysilane can help sensors react only to target molecules, making lab tests faster and more accurate. Small design tweaks using the right silane translate to better patient care and greater trust in diagnostic results.

Handling chloromethyl(methyl)dimethoxysilane takes some care because of its reactivity and the need to avoid moisture during its use, but strict safety routines in labs and industry prevent accidents and exposure. Companies have put big effort into controlling emissions and storing waste. As chemists and engineers look for safer, less hazardous alternatives, some progress comes from using better equipment and training, yet research keeps pushing toward new molecules with fewer risks and lower environmental impact.

Silane chemistry keeps moving forward as materials science asks for smaller, stronger, and more adaptable surfaces. Learning from past experience, industry leaders and researchers focus on making treatments more reliable, safer to handle, and more eco-friendly. That means better surfaces in the lab, on our devices, and across smart technologies—driven by the enduring usefulness of clever molecules like chloromethyl(methyl)dimethoxysilane.

A lot of people working with specialty chemicals get used to odd-smelling bottles and complicated labels. Chloromethyl(methyl)dimethoxysilane is one of those compounds that can really change your perspective on safety. It’s highly reactive, prone to releasing corrosive vapors, and it won’t forgive lazy habits. I’ve handled volatile organosilanes in research and small manufacturing settings, where proper technique mattered more than any expensive glovebox.

This silane reacts violently with water, turning every drop of humidity or sweat into hydrochloric acid gas and heat. As little as a careless drip from a leaky faucet or a cloud of breath in the wrong spot can spell disaster. Left alone on a shelf, it slowly breaks down, creating more pressure inside the bottle. One forgotten sample in our lab popped its seal after a summer power outage knocked out the air conditioner.

To store this stuff safely, you want a few things: a cool place, no sunlight, and no water nearby. Standard fridges rarely cut it; chemical stores use explosion-proof refrigerators with tight temperature control. Well-ventilated, dedicated storage cabinets with secondary containment trays keep drips and spills from spreading. Shelves stay uncluttered, with containers spaced apart, which beats digging through a pile of old bottles and banging one by accident.

Never stash this chemical with acids, bases, or oxidizers. Years ago, a careless delivery person dropped a bottle near a bleach jug, which released a cloud of gas—fortunately outside. Separate storage is no joke.

Labeling matters more than most assume. Everyone in the lab should recognize the hazard, so labels stay bold, updated, and clearly marked. Unambiguous hazard symbols help, since newcomers may not recognize chemical names. Opening the container feels like surgery: full goggles, face shield, gloves (nitrile or better), and an apron. I’ve seen folks try to cheat with thin gloves; they often learn the hard way that these silanes soak right through.

Fume hoods aren’t optional. Every transfer or weighing happens behind glass, with the sash low and the airflow maxed. One time, a visiting scientist mixed up the sash heights and caught a lungful of vapor—straight to the emergency shower.

Any spill requires quick action. Pouring sand or using spill pads that specifically absorb organosilicon chemicals stops the spread. Water only makes things worse—dry chemical agents and an emergency plan keep people out of harm’s way. Waste containers stay tightly closed and stored far from anything flammable or reactive, then shipped promptly for disposal.

Mismanagement doesn’t just put people at risk—it often triggers bigger costs from ruined instruments or shutdowns. Better practice starts with clear procedures, frequent drills, and a culture where safety gear isn’t stashed under benches. These habits travel with you, shaping how every chemical gets treated. Good storage and careful handling mean fewer surprises and a work environment where you notice hazards before they show up in an accident report.

Chloromethyl(methyl)dimethoxysilane gets used in a lot of industrial settings. Some people know it from the labs, others probably never heard the name once. I’ve worked in research and seen firsthand what can go wrong when folks underestimate new or unfamiliar chemicals. This one raises some flags because of what the ingredients bring to the table—mainly the chloromethyl group and silicon backbone paired with methyl and methoxy groups. It sounds like a chemistry lesson, but this really gets to worker safety and even environmental health.

Vapor from this compound acts as a strong irritant to the skin, eyes, and lungs. I remember a colleague who managed to get a small splash on a gloved hand. The glove didn’t last for long. A red, burning welt soon followed. This matches what the science says: burns and eye damage are serious risks. The volatility means workers can inhale the vapor almost anywhere the liquid spills or leaks, making tight ventilation and good respirators absolutely necessary. Extended exposure may scar tissue or trigger asthma-like symptoms for sensitive folks.

Health authorities warn about the potential for long-term effects, since alkyl chlorosilanes can release hydrochloric acid when they react with water (think sweat, or any humidity in the air). That means not just burns, but also the threat of toxic gas filling an enclosed area. A couple of breaths make throats itch and swell, with damage possible in the windpipe and lungs. Emergency rooms see these cases more often in industrial areas that process silicones, especially when training or equipment comes up short.

This chemical also carries a fire risk. Flammable vapors float at room temperature, looking for a spark. In one incident I watched unfold, a static discharge from synthetic clothing ignited a spill before anyone registered the danger. A few seconds felt like an eternity, with alarms blaring and everyone hustling to introduce foam extinguishers instead of water, since water just makes the reaction worse. Chloromethyl(methyl)dimethoxysilane reacts strongly with water, releasing heat, hydrochloric acid, and sometimes even combusting outright. That means regular fire equipment can sometimes make a bad situation even worse.

Spills outside the workplace introduce yet another set of risks. Runoff seeps into water systems, where the compound hydrolyzes and poisons aquatic life by forming acid and siloxanes. No fish or water bug stands a chance if concentrations tip even modestly high. That risk only grows near manufacturing plants, particularly in rainy seasons. Regulators point to the need for double-walled storage and leak monitors. My own experience says every drum and transfer line can develop a weak spot if ignored.

Engineering controls like fume hoods and sealed pipettes do more to control exposure than any single safety rule or personal habit. I always stress that workers need not just gloves, but the right gloves—some materials melt on contact. Emergency showers and eyewash stations have to go hand-in-hand, with everyone trained to use them. Regular safety drills help keep panic at bay, too. Updates to chemical inventories and clear labels set the stage for quick response if something spills.

The bigger picture means more than waiting for regulators to step in. Companies who invest in staff education and maintain up-to-date safety gear protect not only their workers, but the wider community. It only takes one oversight to turn an ordinary shift into a crisis. My hope is that folks who regularly handle tricky silanes never face preventable consequences just because someone took a shortcut or skipped a rehearsal. Real safety begins on the shop floor and builds from there, chemical by chemical.

In specialty chemicals like Chloromethyl(Methyl)Dimethoxysilane, purity isn’t just a spec sitting on a piece of paper—it steers everything from process safety to end product consistency. As someone who’s had their hands in a lab flask or two, I’ve seen how even the smallest impurity can send a batch sideways, fouling up yields, creating off-colors, or—worst of all—putting people and equipment at risk.

Buyers, chemists, and quality assurance folks want certainty. Without an agreed purity level, nobody can trust what goes into or comes out of that supply chain. So, every barrel or drum that gets shipped across the globe has its Certificate of Analysis (CoA) stamped with number after number that prove its contents. For Chloromethyl(Methyl)Dimethoxysilane, this detail means more than just compliance; it keeps the whole system running smoothly.

Labs and factories rely on Chloromethyl(Methyl)Dimethoxysilane for a whole range of silicone-based products and specialty polymers. Most commercial suppliers set the specification at over 98% purity—often you’ll see CoAs quoting 98.5% or even up to 99%. Below that mark, the chemical starts to carry leftover solvents, unreacted starting materials, or by-products that endanger both product performance and worker safety.

GC (Gas Chromatography) usually checks the purity call, and the residue—less than 2%—gets broken down into measurable parts, pointing to specific impurities: chlorinated silanes, possibly traces of methanol, and sometimes even bits of unknown origin. These side-products can be hazards themselves, defeating the point of technical grade or higher.

Chemists and plant managers don’t leave purity up to luck. Purification strategies get planned from the ground up, focusing on column distillations under inert gases, closed-loop transfer, and strict temperature control. Good facilities hit the 98%+ target batch after batch.

Still, nothing in chemistry ever stays static. If someone runs into purity issues, usual suspects include improper storage, contamination during bottling, or a reaction gone off-spec. In those cases, facilities either purify again or dump those lots, losing money and time. That’s a hard lesson I saw firsthand—watching a week’s work go down the drain after an air leak that oxidized a drum overnight. Not every problem can be fixed with distillation; sometimes prevention is the only tool.

High purity matters most for companies pushing for electronics, pharmaceuticals, or advanced coatings. Their specs are unforgiving. Anything less than 98% Chloromethyl(Methyl)Dimethoxysilane, and you might as well be working with a different molecule. Lower grades can slip through for some basic industrial applications, but precise work demands strict standards.

Those end users keep their own testing protocols, checking every incoming drum before it hits the production line. If purity looks low, shipments get rejected. Reputable suppliers avoid this by regular audits and transparent CoA documentation, and they share every test variable—temperature, method, retention times—as proof that the spec isn’t just hype.

Purity only keeps climbing in importance as products get more complex and regulations grow sharper. To stay competitive and safe, chemical producers keep refining purification processes, invest in better analytical equipment, and focus on honest reporting. The end result? Fewer surprises, better products, and a whole lot more trust from everyone involved.

| Names | |

| Preferred IUPAC name | chloromethyl-dimethoxy-methylsilane |

| Other names |

Dimethoxy(methyl)chloromethylsilane Chloromethyl(methyl)bis(methoxy)silane Silane, chloromethyl(methyl)dimethoxy- Dimethoxy(methyl)(chloromethyl)silane |

| Pronunciation | /ˌklɔːroʊˌmɛθɪlˌmɛθɪldaɪˌmɛθɒksiˌsaɪleɪn/ |

| Identifiers | |

| CAS Number | 2212-10-4 |

| Beilstein Reference | 1367933 |

| ChEBI | CHEBI:88275 |

| ChEMBL | CHEMBL2107818 |

| ChemSpider | 127678 |

| DrugBank | No DrugBank entry found |

| ECHA InfoCard | 06cf0b528a00018d0001 |

| EC Number | 412-740-0 |

| Gmelin Reference | 85754 |

| KEGG | C18609 |

| MeSH | C14H33O2Si3 |

| PubChem CID | 12233000 |

| RTECS number | VP8775000 |

| UNII | X1W8R82OII |

| UN number | UN2667 |

| CompTox Dashboard (EPA) | DTXSID4020760 |

| Properties | |

| Chemical formula | C5H13ClO2Si |

| Molar mass | 136.66 g/mol |

| Appearance | Colorless transparent liquid |

| Odor | Pungent |

| Density | 1.02 g/mL at 25 °C (lit.) |

| Solubility in water | reacts |

| log P | 0.8 |

| Vapor pressure | 13 mmHg (20 °C) |

| Acidity (pKa) | 13.6 |

| Basicity (pKb) | pKb: 3.5 |

| Magnetic susceptibility (χ) | -6.38 × 10⁻⁶ cm³/mol |

| Refractive index (nD) | 1.381 |

| Viscosity | 0.6 mPa·s (25 °C) |

| Dipole moment | 1.95 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 296.0 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -243.7 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | Std enthalpy of combustion (ΔcH⦵298) of Chloromethyl(Methyl)Dimethoxysilane: -2760 kJ/mol |

| Pharmacology | |

| ATC code | |

| Hazards | |

| GHS labelling | GHS02, GHS05, GHS07 |

| Pictograms | GHS02,GHS05,GHS07 |

| Signal word | Danger |

| Hazard statements | H225, H301, H314, H331 |

| Precautionary statements | P210, P220, P234, P260, P261, P264, P271, P280, P301+P330+P331, P303+P361+P353, P304+P340, P305+P351+P338, P308+P311, P310, P311, P312, P330, P363, P370+P378, P403+P233, P404, P405, P501 |

| NFPA 704 (fire diamond) | 3-4-2-W |

| Flash point | 44 °C (Closed cup) |

| Autoignition temperature | 260 °C |

| Explosive limits | 6-17% (V) |

| Lethal dose or concentration | LD50 Oral Rat 2107 mg/kg |

| LD50 (median dose) | LD50 (median dose): Oral, rat: 500 mg/kg |

| NIOSH | GVG79500 |

| PEL (Permissible) | PEL: Formaldehyde 0.75 ppm |

| REL (Recommended) | 0.005 ppm |

| IDLH (Immediate danger) | Unknown |

| Related compounds | |

| Related compounds |

Trimethylchlorosilane Methyltrimethoxysilane Chloromethyltrimethoxysilane Dimethyldimethoxysilane Methyltrichlorosilane |