Chloromethyltrichlorosilane didn’t fall from the sky as some obscure lab fluke; its story traces back to mid-20th century chemical innovation, tied closely with the explosion of organosilicon chemistry. Industry started looking at silanes as new ways to craft specialized plastics, coatings, and advanced materials. In university labs, researchers pushed to modify silicon by attaching all sorts of functional groups hoping for new reactivity. It quickly became clear that attaching a chloromethyl group to trichlorosilane unlocked a whole new set of options. Industrial demand for coatings and adhesives fueled interest, while global chemistry giants refined routes for bulk production. Patents filed in the 1960s pointed toward a future with more chloromethyltrichlorosilane in everything from complex electronics to coatings for everyday products.

You don’t often see chloromethyltrichlorosilane on store shelves. It doesn’t get marketed toward everyday users, since it belongs to a specialized family of reactive silanes. This chemical stands out because the chloromethyl group attached to silicon has both reactivity and versatility. Manufacturers and researchers value it for its ability to add silicon-based groups to a huge number of organic and inorganic surfaces. It’s found under several trade names, each one catering to a different market—composite producers, electronics manufacturers, or research suppliers. Chemists often rely on this substance for surface modification tasks that require reliable, predictable bonds and want to keep the chemistry straightforward without introducing excess byproducts.

Chloromethyltrichlorosilane shows up as a colorless to pale yellow liquid. Unmistakable sharp smell hits right out of the container—a reminder to work with caution. It has a boiling point that sits around 180°C, making it a bit volatile but not impossible to handle. The molecule is dense and reactive, especially with water, where it hydrolyzes fast and gives off hydrochloric acid fumes. It dissolves in most common organic solvents. As reactive as it is, it doesn’t hang around long in humid air, since moisture breaks it down quickly. This substance always wants to latch onto surfaces or react with nucleophiles, making it a toolbox staple but a clear hazard outside controlled environments.

Industrial suppliers don’t take shortcuts with their documentation. Chloromethyltrichlorosilane is typically sold between 96–99% purity. Containers carry warning symbols for corrosive and toxic contents, along with information about molecular weight, storage temperature, and shipping classification (UN 2987 for hazardous goods). The MSDS backs up the warnings with persistent advice about glove types and eye protection. Packaging choices usually involve amber glass or tightly sealed steel drums to keep moisture and light at bay. Every label reinforces the risks: it takes only minutes of exposure to high humidity before the chemical starts breaking down, creating byproducts that nobody wants floating around.

Labs and factories tap into two main production strategies. One route involves substituting the methyl group in methyltrichlorosilane with a chloromethyl group through chlorination using formaldehyde and chlorinating agents like phosphorus pentachloride. This method needs precise temperature and reactant control to avoid runaway byproducts and maximize the yield. Another common approach starts with silicon tetrachloride and reacts it with chloromethane under catalysis, often with aluminum chloride. Both syntheses produce a hot chemical mixture that demands careful workup, plus distillation under an inert atmosphere to ensure pure product. I’ve seen plenty of scaling headaches when larger reactors mean more heat and even riskier releases, pointing to the critical need for skilled technicians and strong engineering controls.

Versatility shines in the reaction chemistry of chloromethyltrichlorosilane. The trichlorosilyl moiety reacts with water, alcohols, and amines, helping graft silicon-based chains onto organic or inorganic materials. Surface chemists use it to modify glass slides, turning slippery, hydrophobic, or reactive depending on what the end-user needs. The chloromethyl arm opens doors for further functionalization. Once the silylation step is finished, coupling agents and catalysts can transform that side of the molecule, building in new groups for applications in polymers or even pharmaceuticals. In one project, our team found it straightforward to anchor bulky organic frameworks to silicon wafers for microchip development, reducing unwanted interference and improving product stability.

Chemical markets never stick to a single name. Anyone looking for this material may also encounter designations like (Chloromethyl)trichlorosilane, trichloro(chloromethyl)silane, or CMTC. Trade catalogs may stick their own spin, sometimes just calling it “CM Silane.” CAS number 1558-25-4 connects all these references. For those of us in the lab, memorizing the variations helps sidestep confusion when ordering for a project or checking literature references that came out of different countries or corporate labs.

Chloromethyltrichlorosilane offers no margin for error on the safety front. Splashes or inhaled fumes pose threats to eyes, skin, and lungs. Industrial hygiene guidelines require full-face respirators, nitrile gloves, and chemical-tight suits in manufacturing settings. Even small spills call for emergency protocols because hydrogen chloride can gas off quickly. Storage policies demand dry, well-ventilated areas, sometimes with positive pressure and scrubbers for air handling. Routine air sampling and solvent-resistant work surfaces keep exposures under regulatory limits. Training counts for everything—one gap in PPE or a lapse in handling can close a line and endanger coworkers. Over the years, new monitoring and automated transfer systems have improved safety records, but direct handling always carries risk.

Industries and labs turn to chloromethyltrichlorosilane whenever there’s a need to tale surfaces or connote fine control of silicon-to-molecule linkages. Fabrication of composite materials and advanced coatings leans heavily on its reactivity. In microelectronics, engineers use it to modify MOSFET gate insulators and tether organic groups to silicon wafers, tuning device performance. The chemical also stars in the functionalization of glassware for DNA and protein microarrays, providing a stable attachment point that resists washing or chemical degradation. I’ve watched biomedical researchers rely on it for making slides that tolerate repeated cell culture and analysis without losing functional layers. Anywhere tough, tailored surfaces matter, applications for this silane tend to follow.

Academic and industrial groups keep pushing into new territory with chloromethyltrichlorosilane. Ongoing research targets more selective functionalization so molecules can stick only where wanted on complex surfaces. Material scientists experiment with new polymer coatings for corrosion resistance and drug delivery. There’s a constant search for alternative routes to make and handle the chemical with fewer byproducts and lower energy input. Each round of journal articles seems to bring another clever way to drop reagents onto a wafer, then transform them into next-generation biosensors or organic electronics. From my own collaborations, I’ve seen startups try flow chemistry to limit waste and boost throughput, aiming for affordable, large-scale applications.

Hazard assessments for chloromethyltrichlorosilane stay under review as more long-term exposure data gets published. Short-term, even dilute vapors cause irritation to the lungs, eyes, and skin. Animal studies have raised alarms about pulmonary effects with repeated inhalation. Direct contact burns deeply and heals slowly. Environmental release, even in trace amounts, can acidify local water sources and threaten aquatic species. Regulatory agencies demand strict exposure limits, down in the single-digit ppm range for airborne concentrations. In toxicology circles, the hunt continues for more thorough breakdowns of chronic exposure risks, metabolism, and transport within the body. Several teams now screen downstream byproducts for genotoxicity or persistent environmental footprints, hoping to pinpoint and mitigate secondary hazards.

Industry trends all point toward specialized, higher-purity organosilicon chemicals, and chloromethyltrichlorosilane keeps a role in that mix. Next-generation electronics, cleaner energy devices, and biomedical tools all lean on robust silicon linkages that this molecule can help create. Sustainability questions keep rising—how can we cut waste and guard against accidental releases along the supply chain? I see potential in smarter containment, closed-loop synthesis, and digital tracking of hazardous batches. The future for chloromethyltrichlorosilane won’t drop demand overnight but will force suppliers and researchers to chase greener synthetic routes, tighter process controls, and new applications where its chemical strengths meet safety and environmental stewardship head-on. If the industry takes these directions seriously, chloromethyltrichlorosilane could help drive the next round of material breakthroughs without repeating the mistakes of the past.

Chloromethyltrichlorosilane sounds like a mouthful, but in a chemical plant, the name shows up a lot. This compound offers a strong backbone for building silicon-based materials. Folks working with silicone rubbers, adhesives, or water-repellent coatings probably depend on it—just not directly by name. The secret lies in its reactive groups, which link up with organics and inorganics, making it a favorite for surface treatments. Some glass and ceramics use it to go from attracting water to shaking it off with ease. This matters on rainy days, especially if those materials hold up buildings or tech equipment.

I remember a friend, a materials engineer, grumbling about moisture in solar panels. Turns out, a simple coating from a silane like this one keeps water off and lets the panels last longer outdoors. People want solar panels to perform rain or shine, so skipping over this compound would cut their life short. In electronics, tiny traces apply on silicon wafers, letting components sit tight during production. Stuff like this makes it into everything from big sand-cast windows to microchips. That's probably why chemical suppliers stock it by the barrel.

Chemicals with “chloro” in the name draw attention for a reason. Chloromethyltrichlorosilane can turn nasty in the wrong hands. It reacts sharply with water and dumps HCl gas into the air. Workers dealing with open barrels or leaks feel it in their eyes or lungs, and that's no small deal on a busy production line. Wearing gear isn’t optional—skin exposure or inhalation prove hazardous. The Environmental Protection Agency and OSHA both mark it for close oversight. Proper ventilation, closed transfer systems, and real spill drills all play a part in better safety records.

Even minor leaks at a plant could lead to big headaches, especially if runoff touches soil or water. These silanes break down, but their byproducts linger for a while. This means chemical companies owe it to communities to track and control waste, not just hit the numbers in annual reports. Emergency responders train specifically for these incidents, making use of neutralizers and protective clothing. Open communication from plant management and real-time alerts build trust, which matters when folks live nearby and worry about air quality.

Chloromethyltrichlorosilane represents old-school chemistry, but new ideas are breaking ground. Researchers keep working on safer substitutes, hoping to cut out the risks without sacrificing use. Companies investing in green chemistry win points with customers, regulators, and workers. Engineers lean on process innovation—like improved reactors, safer packaging, and digital leak detection—to shrink hazards.

This storyline keeps coming up wherever practical needs meet tough technical problems. A reliable compound like this one bolsters industries: glass stays clean, circuits run better, and outdoor gear lasts longer. Facing risks head-on with strong protocols and city-level engagement lets the benefits reach the shelves—without the fear. From my own visits to plants and conversations on job sites, trust and transparency matter just as much as science in keeping people safe and products dependable.

Chloromethyltrichlorosilane isn’t just another chemical sitting in a lab. It reacts harshly with water, giving off hydrogen chloride, a seriously nasty gas for your lungs and skin. I’ve spent time with lab workers and seen firsthand how a single splash can leave burns or cause breathing trouble nobody soon forgets. People hear about shelling out for proper gear or good training and think ‘overkill’ until something goes sideways. Stories about close calls stick for a reason – nobody shrugs off an exposure accident.

Contact with this chemical feels like inviting trouble into your lungs and onto your skin. The fumes irritate the nose, throat, and chest almost instantly, and if that reaction feels strong, your body’s warning you for good reason. Splashes can burn, not just sting. If that isn’t enough, improper handling around moisture or water means you’re gambling with toxic gas clouds in a hurry. If you spend much time with industrial safety stats, you know one out-of-place drop can send someone to the hospital.

Folks working with chloromethyltrichlorosilane should respect the basics—think heavy-duty chemical goggles, nitrile gloves, lab coats or aprons that don’t fray at the wrists. Airflow isn’t a minor issue. Real fume hoods matter, not just cracked windows. Anyone relying on open doors seriously underestimates how quickly vapors build up. In labs and warehouses I’ve visited, the best managers run ventilation checks regularly, and they never accept workarounds like a fan propped up in the corner.

There’s a lot of talk about protocols in safety manuals. In real-world labs, hands-on drills and ‘what if’ scenarios make the difference. People remember demonstrations far longer than a stack of instructions. Everybody should know how to respond if a bottle tips or a cloud of fumes gets loose. Eyewash stations and chemical showers need to stay unblocked and working—no storing boxes in front, no skipping the maintenance checks. Lab techs should rehearse fast responses, not just read about them.

Safe storage eats up space and sometimes budgets, but the cost of doing it wrong is higher. Tough, sealed containers keep moisture out, and no one should ever store chloromethyltrichlorosilane near anything reactive or damp. I’ve heard stories about close shaves from chemicals stored too close together or left in poorly labeled bottles. Keeping materials separated and clearly marked can be the difference between a regular day and an emergency.

Workplace safety runs on trust—between bosses, workers, and safety officers. Regular retraining, open reporting of near-misses, and a steady push for better equipment help keep people sharp without building resentment. I’ve watched companies with an open-door safety mindset dodge injury clusters the rest of the industry struggled with for months. Creating a culture where nobody’s too proud to gear up or double-check a seal means accidents stay rare and people go home whole.

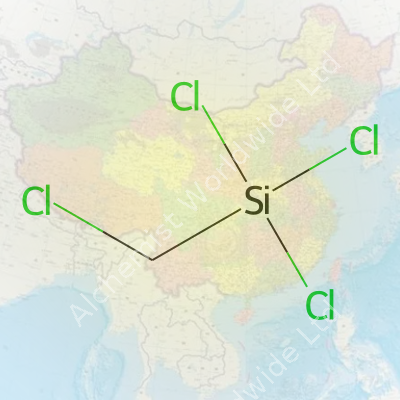

Chloromethyltrichlorosilane carries the chemical formula CCl3H3Si and a precise molecular weight of 181.48 g/mol. In daily lab routine, its formula is usually written as CH2ClSiCl3. This stuff shows up a lot in applications that connect chemistry to everyday products. From a teaching perspective, handling names like these helps anyone keep sharp about chemical structures. Three chlorine atoms linked up with a silicon, plus a chloromethyl group, shape its utility.

There’s a reason companies look toward molecules like chloromethyltrichlorosilane. The trichlorosilane core delivers strong reactive spots, allowing modifications other chemicals can’t provide. On the job, I’ve seen chemists reach for this reagent when building protective layers on glassware or tuning up coatings for electronics. It’s the way these atoms stack and connect — that’s the story behind its popularity. It bonds tightly with glass and forms a shield that fights off moisture.

Certain lab tasks just lean on predictable chemistry. That’s where molecular formulas matter more than most people expect. With the chlorine-heavy backbone, this compound anchors itself to surfaces and gives other ingredients a place to latch on. Each element in the formula does some lifting. Silicon offers backbone stability, the chlorines make it reactive, and that one carbon pulls in new features if you need it to.

Working with chemicals like chloromethyltrichlorosilane means you see why safety always comes first. That mix of chlorines and silicon packs a punch for the eyes, skin, and lungs. I remember one time a colleague got a small splash on a glove. The degradation happened fast. Proper gloves and a sturdy fume hood — those habits count, every time. Exposure to moisture in the air starts up a reaction that gives off hydrochloric acid, making a strong case for double-checking seals on storage containers.

Chemical formulas aren’t just trivia; they alert you to hazards. Chlorinated silanes never cut corners with safety. Their sharp smell and fumes remind anyone in the lab to review emergency rinses and ventilation. Over years of teaching, it’s surprising how even experienced folks forget how fast reactive silicon moves with water or air. The right training keeps bad surprises from happening.

Reducing risks with chloromethyltrichlorosilane comes down to routine checks and buddy systems. Labs benefit from clear labeling and regular refresher courses, not just for newcomers. I once worked at a plant where everyone had to sign off on training updates every six months. That cut spills and mix-ups to a minimum. Investing in better storage containers and emergency showers pays off. Silicone-based gloves and splash-proof face shields give people peace of mind.

On a bigger scale, substituting less volatile reagents when possible protects health over the long run. Some companies now research alternatives that carry less toxicity and lower environmental exposure. Strict rules for waste disposal also keep contamination issues out of the water supply. Where local guidelines exist, following them isn’t just paperwork — it keeps communities and staff safe.

Knowing the chemical formula and molecular weight may sound basic, but those details steer plenty of decisions in manufacturing and safety planning. Beyond textbooks, recognizing each molecule’s role ramps up safe, efficient work. The structure and weight frame everything from shelf life to product performance. Getting these facts right helps researchers, workers, and the public feel confident in how technology develops and stays responsible.

Chloromethyltrichlorosilane doesn’t just sound intense; it actually causes big trouble if you cut corners. This stuff reacts with water and humidity, releasing hydrochloric acid gas. I remember during my early days in the lab, a leaky drum led to a sharp stinging in my nose, watery eyes, and a mad scramble for fresh air. That memory sticks. You never forget the sting of hydrochloric acid, even in vapor form.

The biggest threat? Moisture. Even a little condensation can trigger enough gas to harm people in the area. Hydrochloric acid eats through metal, skin, and lungs. I once saw a metal shelf warp and rust out from a few drops accidentally left on it overnight, so no shortcuts with storage.

Glass doesn’t cut it either, since over time, chlorosilanes can corrode glass and pop a slow leak. Only special types of metal work. Stainless steel often wins out, but only grades that handle acids. I still check for pitting on tank fittings out of habit. Seals and gaskets—always from Teflon or a trusted silicon rubber—since classic rubber melts away.

Chloromethyltrichlorosilane lives best in a cool, tightly controlled space. You want low humidity and no wild swings in temperature. Spiking heat bumps up vapor pressure, making leaks way more likely. We kept our bottles in ventilated cabinets, with temperature sensors rigged to alarms. If the AC ever died, believe me, you’d hear about it before you felt it—because every chemist gets jumpy with anything that hisses or drips in the wrong spot.

Inventory always gets double-checked. I label each drum with the date, hazard warnings you can’t miss, and storage instructions. Record-keeping keeps everyone honest, so nobody just grabs a flask or moves a drum into a hallway “until tomorrow.” Lock the room and restrict keys to those trained to handle emergencies. A rookie once opened a drum and set off alarms. Experience and training matter.

People in the know never store chloromethyltrichlorosilane near flammable materials or oxidizers. Even organic solvents can start a runaway reaction. Shelves should be solid, with spill trays waiting to catch any dribble before it spreads. We always keep a chemical spill kit close by, stocked with soda ash or lime to neutralize acids, and a couple of sets of goggles for the inevitable splashes mid-transfer.

Fire crews in my area received special instructions on how to handle leaks or fires involving this chemical, because a typical water spray worsens things. You use dry extinguishers and then ventilate the whole site, clearing out the gases as fast as possible.

Good storage keeps trouble inside the bottle, not floating through the building or leaching into drains. Everyone on a shift deserves full instructions and the right gear—respirators, gloves, long sleeves, and regular checks on the bottles. An incident in a poorly marked storage room once sent someone to the ER with burned hands and breathing issues. That shook the team awake for good.

Clear rules, trustworthy gear, and regular reviews catch problems early. I recommend printed reminders near every storage site. In an emergency, simple language and sharp warnings save more than just time—they prevent real, lasting harm. Memory serves as the best teacher, but it’s one lesson you don’t want to learn the hard way.

Chloromethyltrichlorosilane sounds like one of those chemicals you hope never to see outside of a textbook. In practice, it often shows up in facilities tied to silicon-based industries, particularly in making silicone polymers and sealants. Handling it can turn risky fast. It reacts violently with water and air moisture, releasing hydrochloric acid and other gases that can damage lungs and skin. Sometimes, chemicals give off a smell to warn you. This one manages to stay under the radar—exposure risks rely on solid precautions, not just your senses.

If it touches your skin, you’ll probably feel a burning pain, but the deeper tissue keeps taking the hit. You might see blisters or deep burns, not just surface redness. If you breathe it in, the body fights back with a sore throat, chest tightness, and, sometimes, a cough that won’t quit. Eyes face corrosive injuries in seconds, risking vision. The stuff also doesn’t play it cool with fire. Vapors ignite easily, turning any spill into a fast-moving hazard.

Factories and labs using chloromethyltrichlorosilane often run at high pace. Over the years, I’ve seen some folks cut corners—just a minute without gloves, just a splash instead of a full face shield. Sooner or later, that shortcut catches up. The Centers for Disease Control and Prevention (CDC) notes that chemicals like this one generate acute respiratory distress and dangerous burns. In one documented case, people developed severe symptoms in under thirty seconds of exposure.

Accidents rarely unfold in a textbook way. People panic, emergency showers get blocked, or the nearest eyewash station’s empty. All of a sudden, what seemed like a controlled risk becomes a rush to save tissue, lungs, or eyesight. It doesn’t only affect workers. Cleanup teams, and even nearby communities, get swept up in fallout from leaks or fires. The Occupational Safety and Health Administration (OSHA) keeps a close eye on facilities handling chloromethyltrichlorosilane for good reason—lapses cost lives.

If someone takes a hit from this chemical, immediate steps make the difference. On the skin, pull off contaminated clothes right away and drench the skin in running water for at least fifteen minutes. Soap helps but don’t waste time searching for the perfect brand. For splashes in the eyes, pry open the eyelids and rinse with water, aiming for twenty minutes or more. Remove contact lenses right away, but never delay the rinse for that. Inhalation calls for fresh air—move the person outside and loosen anything tight on their body. Breathing stops? Get someone trained to give mouth-to-mouth and call for emergency support as soon as possible.

No home remedies, no waiting to see if the pain “goes away”—hospital care usually follows, even if symptoms seem to clear. If anyone swallows it, doctors don’t recommend trying to make that person vomit; head for emergency care, fast. I’ve seen panic muddle basic steps, which is why ongoing safety training and regular drills matter as much as a well-stocked first aid room. An emergency phone number by every workstation saves precious minutes.

People learn best by doing. Drills involving real spills with harmless substitutes build muscle memory, so the actions come naturally. Clear signage, frequent equipment checks, and encouraging a culture where nobody skips safety gear set the tone. There’s a link between prevention and long-term well-being that gets overlooked until the worst happens. Sharing stories of close calls and best practices among staff brings those dangers out of the manual and into the real world, where they belong.

| Names | |

| Preferred IUPAC name | (trichlorosilyl)methane |

| Other names |

Chloromethyltrichlorosilane Trichlorochloromethylsilane Trichloro(chloromethyl)silane Silane, trichloro(chloromethyl)- |

| Pronunciation | /ˌklɔːr.oʊˌmɛθ.əl.traɪˌklɔːr.oʊˈsɪ.leɪn/ |

| Identifiers | |

| CAS Number | 107-30-2 |

| 3D model (JSmol) | Chloromethyltrichlorosilane JSmol 3D model string: ``` ClC(Cl)(Cl)SiCCl ``` |

| Beilstein Reference | 1209227 |

| ChEBI | CHEBI:35268 |

| ChEMBL | CHEMBL2230533 |

| ChemSpider | 14621 |

| DrugBank | DB11205 |

| ECHA InfoCard | 100.002.657 |

| EC Number | 602-048-00-0 |

| Gmelin Reference | 8572 |

| KEGG | C18630 |

| MeSH | D002697 |

| PubChem CID | 66313 |

| RTECS number | VV5775000 |

| UNII | Y17QH63N6D |

| UN number | UN3265 |

| Properties | |

| Chemical formula | C2H3Cl4Si |

| Molar mass | 218.35 g/mol |

| Appearance | Colorless to yellowish transparent liquid |

| Odor | Pungent |

| Density | 1.348 g/mL at 25 °C |

| Solubility in water | Reacts |

| log P | 1.9 |

| Vapor pressure | 10 mmHg (20°C) |

| Acidity (pKa) | -5.2 |

| Basicity (pKb) | -3.5 |

| Magnetic susceptibility (χ) | -0.000072 |

| Refractive index (nD) | 1.465 |

| Viscosity | 0.65 cP (20 °C) |

| Dipole moment | 1.42 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 331.1 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -140.9 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -1098.8 kJ/mol |

| Pharmacology | |

| ATC code | V03AB32 |

| Hazards | |

| GHS labelling | GHS02, GHS05, GHS06 |

| Pictograms | GHS02, GHS05, GHS06 |

| Signal word | Danger |

| Hazard statements | H301 + H311 + H331: Toxic if swallowed, in contact with skin or if inhaled. H314: Causes severe skin burns and eye damage. H335: May cause respiratory irritation. |

| Precautionary statements | P210, P260, P261, P271, P280, P301+P330+P331, P303+P361+P353, P304+P340, P305+P351+P338, P312, P321, P363, P370+P378, P405, P403+P233, P501 |

| NFPA 704 (fire diamond) | 3-2-2-W |

| Flash point | -2 °C (28 °F) |

| Autoignition temperature | 260 °C (500 °F) |

| Lethal dose or concentration | LD50 oral rat 1900 mg/kg |

| LD50 (median dose) | LD50 (median dose): Oral rat 180 μL/kg |

| NIOSH | MS8585000 |

| PEL (Permissible) | PEL: 5 ppm |

| REL (Recommended) | 0.005 ppm |

| IDLH (Immediate danger) | 5 ppm |

| Related compounds | |

| Related compounds |

Trimethylsilyl chloride Trichlorosilane Methyltrichlorosilane Chlorodimethylsilane Silicon tetrachloride |