Chemists have spent decades tinkering with silanes, chasing better adhesives, water repellency, and new materials for industry. Octylmethyldiethoxysilane stands out as one outcome of this experiment-driven journey. Back in the mid-20th century, when silicone technologies took off, researchers learned that attaching organic groups to silicon changed everything—from flexibility to how surfaces interact with water. Octylmethyldiethoxysilane came into focus as people searched for grafting materials that slip seamlessly into paints, rubbers, and glass treatments. Teams working in Japan, Germany, and the United States shaped standard synthesis routes during the 1980s, laying the groundwork for current production and use.

Manufacturers describe octylmethyldiethoxysilane as a clear, colorless to pale yellow liquid that emits a light, somewhat sweet smell typical of many silanes. Labs and factories rely on this organosilane because it controls how surfaces mix with water or oils. Flooring finishes, exterior concrete treatments, and composite materials benefit from its stable silicon-carbon bonds, which make it tough against environmental wear. Unlike simpler silanes that break down quickly, octylmethyldiethoxysilane sticks around in practical scenarios, ensuring products stay water-resistant for years. The chemical trades under various names, but the unique combination of the octyl, methyl, and diethoxy groups gives this silane its edge.

In daily use, workers notice its moderate viscosity, making transfer and mixing straightforward. The boiling point hovers near 230°C, and it carries a density just a bit below water, letting it float through pipelines and tanks. The long octyl chain gives it a strong hydrophobic character, which—interpreted plainly—means it fights off water at every opportunity. Moisture, of course, makes the story tricky; silanes like this hydrolyze in the presence of liquid water, transforming the ethoxy groups into silanols and ethanol. That’s why experts urge dry conditions from warehouse to worksite. Technicians describe this change as both an asset and a risk, since hydrolysis activates the molecule for surface bonding but can wreck storability.

A typical drum or bottle comes stamped with purity north of 97%, trace moisture kept below 0.1%, and clear identification of molecular weight (246.46 g/mol). Hazard labeling comes straight from GHS and REACH standards, demanding warnings about skin and eye irritation. No one wants a batch that’s turned cloudy, as water contamination means unwanted chemical reactions already started. Trace impurities, usually leftover solvents or silanol byproducts, get listed for large buyers who care about downstream reactions. Shipping papers call attention to the flammability and the risk of forming acidic fumes during combustion.

Producers turn to a familiar pathway: the reaction between chlorosilanes and octyl-containing alcohols under basic conditions. The process sheds hydrochloric acid, and subsequent vacuum distillation scrubs away side products. Ethanol gets introduced in a controlled environment to replace chlorine atoms with ethoxy groups, finishing the transformation. Real-world batches show off careful balance, where temperature spikes and air leaks can botch the whole batch by forcing undesired polymerization or hydrolysis. In my own work with silanes, controlling humidity has always felt like chasing shadows—too much and you’re left with a useless sticky mass, too little and the yield crawls. Manufacturers face the same delicate dance.

Out on the plant floor or in university research labs, octylmethyldiethoxysilane finds use as both a monomeric building block and a surface modifier. The ethoxy groups hydrolyze on wet surfaces, producing silanols that fuse onto glass, silica, or metal oxides. The remaining methyl and octyl groups poke outward, changing how water or oil interacts with the object. Chemists can link this silane to functional groups—amines, epoxies, or more exotic moieties—by clever post-synthetic modification. Such flexibility means huge promise for custom coatings, adhesives, or compatibilizers in tough composite blends. Siloxane linkages formed during curing stages bring real-world toughness, crucial for infrastructure or consumer products.

Depending on where people shop, labels read “Methyloctyldiethoxysilane,” “Diethoxy(methyl)(octyl)silane,” or trade names like “Silquest A-1630.” Chemical catalogs often pin the CAS number 2943-75-1 to the product, making global trade and regulation easier. These terms aren’t empty jargon since matching the correct synonym ensures buyers get the exact isomer or grade they expect. Workers in procurement and regulatory affairs need to double-check SDS sheets and technical bulletins because mislabeled shipments can grind production to a standstill.

Anyone handling octylmethyldiethoxysilane deals with a fire hazard, moderate inhalation risk, and the danger of skin or eye irritation. Storage involves tight-seal containers in cool, dry spaces, away from acids, oxidizers, or water leaks. Personal protective gear matters even for seasoned professionals—gloves, goggles, and sometimes supplied-air respirators depending on the scale. Emergency spill procedures call for sand, non-sparking tools, and swift removal of ignition sources. In the regulatory landscape, compliance with OSHA, REACH, and GHS standards creates a buffer for workers and the environment. I remember one slip-up at a job site: someone ignored a “no water” sign, and a cloud of ethanol and irritant fumes filled the room within seconds. The take-home message from incidents like this keeps safety briefings fresh in everyone’s mind.

Coating experts take a shine to octylmethyldiethoxysilane for creating hydrophobic layers on stone, masonry, and cement. Builders rely on it to keep infrastructure drier and longer-lasting, from bridges to sidewalks—moisture just beads up and rolls away thanks to that long alkyl chain. It pops up in automotive glass primers, softening the edge against scratching and fogging. Polymer chemists blend the molecule into specialty rubbers and plastics to boost compatibility with silicones and other hydrophobic fillers. It doesn’t stop there. Electronic encapsulants, solar panel sealants, and even certain medical devices benefit from the reliable surface properties this silane hands over.

Academic labs treat silanes like octylmethyldiethoxysilane as a launchpad for new functional materials. Cutting-edge efforts go beyond just making concrete water-resistant—now the focus sits on smart coatings, antifouling solutions, and biomedical interfaces that sense or react to their surroundings. At big chemical firms, R&D divides toss this silane into test panels alongside all the usual suspects, measuring abrasion resistance or chemical fouling. The race for more eco-friendly silanes, lower energy production methods, and chloride-free synthesis pushes this molecule into the spotlight for green chemistry projects. Graduate students worldwide, notebooks full of trial-and-error diagrams, help move the needle on new derivatives that break through cost or performance limits.

Toxicologists look hard at organosilanes for both acute and chronic effects in the lab. Most studies show that octylmethyldiethoxysilane doesn’t cause systemic toxicity at workplace exposure limits, but skin and eye irritation pose day-to-day risks for handlers. Tests in aquatic organisms highlight trouble if waste streams aren’t contained, urging for robust process containment and effluent treatment. Some reports suggest the ethoxy breakdown products, like ethanol, bring familiar hazards—subtle but well-documented over prolonged exposure. Calls for more biomonitoring and long-term studies grow each year, especially as these silanes end up in road dust or industrial run-off. I remember conversations with safety officers where data gaps led to extra caution—no one wants a reputation for overlooking evidence, especially with regulatory agencies watching closely.

Octylmethyldiethoxysilane finds itself at an interesting crossroads. As industries demand sustainable and lower-VOC solutions, this silane has the chemical backbone to adapt, whether through green synthesis or as part of hybrid materials that replace less-friendly coatings. Construction, transport, and electronics technology continue evolving, pushing for smarter, longer-lasting surfaces. If researchers crack the code on renewable feedstocks or zero-emission manufacturing, the molecule’s popularity will rise further. The untapped potential in microelectronics and bioengineered surfaces—where every atomic layer counts for performance—keeps innovators tinkering with how this silane connects to new partners on a molecular level. Add to that tightening safety standards and environmental rules, and octylmethyldiethoxysilane stands ready for its next chapter.

Octylmethyldiethoxysilane probably sounds like something pulled out of a lab notebook, but its influence reaches much farther than scientific curiosity. In the real world, this silicon-based compound lives quietly in a lot of products that touch daily lives—from waterproof raincoats to smartphones. Its key trick comes from bridging the world of water-proofing and surface protection, and this is where the action happens.

Let’s picture a new glass skyscraper gleaming downtown. A week later, rain pelts its windows, followed by a layer of grime from traffic. With coatings made from Octylmethyldiethoxysilane, the building’s owners face less scrubbing. This chemical seeps into the glass surface, turning it from a magnet for water and dirt into something water rolls right off. The result: cleaner windows, much less elbow grease.

The magic doesn’t stop at windows. Smart device screens also get a visit from this compound. You probably don’t think about it as you swipe, but those fingerprints and smudges wash off a little easier. That happens because the screen has been treated with a protective layer that repels water and oil—functions made possible by this silane.

Work boots stomp through puddles and roads see winter salts—all of these challenge surfaces daily. Octylmethyldiethoxysilane steps in for concrete, brick, and stone, conferring them with a knack to repel rain and keep decay at bay. The water can’t soak in, so that siding, patio, or plaza holds up better through tough seasons.

As someone who helps family remodel a mid-century house, battling crumbling mortar and stubborn stains, I’d bet on this chemical as a modern-day fix. Once applied, it soaks into the pores of the concrete, creating a barrier you can’t feel but will notice when rain doesn’t leave that telltale damp patch. Fewer repairs, longer intervals between renovations, lower costs for families and cities.

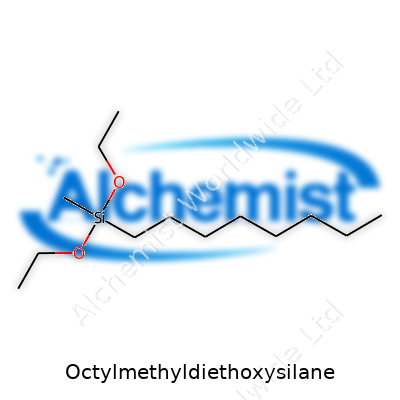

Octylmethyldiethoxysilane has a structure that helps it stick to minerals like glass and stone. Part of its molecule attaches to the surface, while the rest pushes away water and oil. That’s why it’s valued in coatings and sealers—they last longer than old formulas that only formed a skin.

Chemicals in products always deserve a closer look. From building trade folks to parents buying baby products, there’s a growing demand for solutions that work but also break down safely. Octylmethyldiethoxysilane doesn’t stick around in water or soil as badly as older alternatives, but it still can’t be treated lightly. Manufacturers and regulators need to keep pace. Testing for toxicity and persistence, encouraging safer formulations, and pushing transparency in labeling all offer a path forward.

The story of Octylmethyldiethoxysilane isn’t just about molecules and micro-layers. It’s about surfaces holding up through rainstorms, gadgets surviving spills, and homeowners saving cash. Responsible use means advances in chemistry help, not hurt. That calls for engineers who care, consumers who ask questions, and standards that evolve with new discoveries.

Octylmethyldiethoxysilane has become a common ingredient in modern manufacturing. You find it in surface treatments, construction materials, electronics, and sometimes in products on store shelves. Folks working in labs or factories handle it every day. While it makes materials more water repellent and durable, questions pop up about whether coming into contact with it could harm people.

The chemical carries a long name, and also a safety warning. The European Chemicals Agency classifies octylmethyldiethoxysilane as “hazardous,” mostly for its ability to cause eye and skin irritation. WorkSafe Australia has the same opinion. If it hits your skin or eyes, pain, redness, or burning follows. Breathing in its vapors—more likely for builders or factory workers—can make throats scratchy or noses stuffy. More serious effects come with high doses, and over time, it could dry out or even damage skin.

No scientist has called it a carcinogen. No animal studies point to reproductive issues or birth defects. In the lab, rodents given large amounts got an upset stomach, but nothing permanent. The U.S. Environmental Protection Agency classifies it as “low toxicity.” The National Institutes of Health has not put out a health alert. So far, most issues happen after direct contact or if safety rules get skipped, not from trace exposure in finished products.

Many people figure chemicals like these only matter to folks working in factories. Yet think about daily life. Touching building materials, cleaning treated tiles, even unpacking new electronics—all common. Every year, more and more people struggle with sensitive skin, allergies, and asthma. Small exposures can add up, especially in kids, old folks, and those with weak immune systems. So even “mildly toxic” stuff deserves a closer look.

After working years in a busy research lab, I remember well the eye-watering sting of chemical splashes and the importance of clean-up habits. One missed drip on a bench left my hand itching for the rest of the day. Even the “less risky” substances become a hassle if people don’t take them seriously. Not all hazards need to be catastrophic; constant mild irritation can make life miserable and add to sick days and doctor appointments.

Factories and work crews often have safety tech ready: gloves, goggles, good ventilation. Where these rules slip—often due to a rush to finish a job or just plain forgetfulness—injuries go up. Businesses with strong training see fewer chemical burns and rashes. It makes sense to ask for safety data sheets before using new products on the job or at home. Looking up that info doesn’t take long and saves a trip to the nurse.

Consumers can help themselves, too. Never mix products with unknown ingredients without reading labels. If a new countertop waterproofs itself or a cleaning spray seems suspiciously powerful, crack a window and wear gloves. Anyone developing red, swollen skin after using a new household product would do well to try something else—no sense in risking a nasty reaction.

Better regulation would force companies to make safety warnings clear and testing thorough. If chemists and bosses put people ahead of profit, less illness follows. No material is worth regular rashes or sick lungs. Pain-free work and home life takes a little caution and a willingness to challenge the idea that anything on a store shelf must be safe.

Octylmethyldiethoxysilane goes by the chemical formula C13H30O2Si. Every day, I see chemistry bridging abstract science and real-world problems. This compound pulls together an octyl group, a methyl group, and two ethoxy groups bonded to a silicon atom. It’s a mouthful, but the way these elements connect creates a substance with a lot of practical use. C13H30O2Si’s most notable features come from the marriage of organic chains with silicon’s stability. In labs and factories, this recipe produces a clear, often oily liquid that finds a home in a surprising number of materials.

Silanes like Octylmethyldiethoxysilane make surfaces repel water and stick better. In coatings and adhesives, that makes a difference. Water beading up and rolling off a fabric, glass, or concrete starts with the chemistry behind this formula. Even without thinking too hard about “surface tension,” most people care about materials lasting longer and working harder. That improvement depends largely on small silicon-based molecules doing what they do best.

During my time working with composite panels, I saw firsthand how minor tweaks at the chemical level change the way materials behave. With C13H30O2Si, the two ethoxy groups react with water or moisture, bonding to surfaces or resins. The octyl and methyl groups turn the outer shell of a surface hydrophobic. This chemistry shrugs off water, stains, or corrosion. Practical benefit shines through: buildings stay cleaner, road barriers fight off the weather, and electronics get a little extra life.

Every chemical brings questions. Weighing benefits against risks needs more than just curiosity—it calls for real-world experience and scientific evidence. Octylmethyldiethoxysilane is not considered acutely toxic, but it won’t simply vanish in nature. Absorbed through skin or inhaled as vapor, silanes can cause irritation, which means folks who use them need solid training and good protection. I’ve worked in environments where missing a glove led to nasty rashes. That drove home the point—respect the chemicals, understand the formulas, learn the hazards.

Right now, pressure builds for greener solutions. Scientists look for ways to make silanes break down faster after use, to lower volatile emissions, and to keep workers safer. Regulators eye every formula’s impact. In response, manufacturers are tweaking recipes and supply chains, looking for less hazardous substitutes with lower impact. Switching to alternative silanes or using protective coatings in smaller amounts both reduce exposure, but they demand solid technical knowledge and investment.

The best path lies in learning from past mistakes and successes. Tracking every step from lab bench to landfill feels tedious, but it develops better products and healthier workplaces. Waste treatment, sealed application systems, and safer packaging all came about because enough people paid attention to the lessons in the chemistry and in the factory. For Octylmethyldiethoxysilane and its peers, the future seems to involve both better science and more careful stewardship. Every chemist and plant manager I know wants cleaner, longer-lasting surfaces. If the next solution is friendlier for people and the planet, so much the better.

Octylmethyldiethoxysilane lives in a world where precision often beats improvisation. In my work with organosilane compounds, I've seen how easy it is to overlook just how fussy they can get without proper storage. Sometimes people underestimate the risks: a bit of moisture, a few degrees’ shift in temperature, and what looked like a clear liquid yesterday shows signs of trouble today. Small mistakes with these chemicals build up, causing loss of product and sometimes even dangerous situations.

Temperature control plays a key role in keeping octylmethyldiethoxysilane in good shape. I keep it around 15-25°C, away from heat sources and no direct sunlight creeping in through windows. One of my early mentors showed me how temperature swings create condensation inside sealed containers. That tiny amount of water can kick off hydrolysis in these silanes, dragging quality down before you even open the bottle again.

This storage tip gets drilled into new chemists for good reason: sudden temperature changes push air and water through imperfect seals, and you do not want water getting into a container with octylmethyldiethoxysilane. Even if just a thin film forms on the container wall, in practice, there's a real risk that the chemical starts to transform. The result? Contaminated product, labs losing money, and sometimes equipment damage from side-reactions.

I’ve had frustrating afternoons hunting down leaks after finding sticky residue around a silane container’s cap. That kind of mess usually comes from poor closure. For these compounds, tightly sealed glass or metal containers work best; plastic doesn’t cut it—sometimes the vapors cause swelling or leaching. In my experience, desiccators are your friends. Water-protective inner bags, extra gaskets, and silica gel packets don’t just make things look official; they give peace of mind that moisture won’t sneak in even during long-term storage.

Labeling also makes a difference, especially in busy storage areas. I’ve seen colleagues skip labeling as “obvious,” just to mix up old and new batches later. Simple dates and product names prevent head-scratching and wasted material. And I always log each opening—knowing which bottle was exposed and for how long dodges surprises down the road.

Spill or not, some folks forget that strong-smelling vapors from organosilanes can drift out each time a bottle opens. I make it a rule to work only inside chemical fume hoods, then return the container to its cool, dark storage corner right after. A few times, I’ve seen overlooked bottles left on benchtops, and every time, I think about the unnecessary risks for everyone in the lab.

Good recordkeeping, disciplined routines, and clear communication form the backbone of effective storage for octylmethyldiethoxysilane. Labs that give team members clear written instructions cut down mishaps, while regular inventory checks mean old stock doesn’t hide out in back corners growing less reliable by the month. Even in small operations, using lockable cabinets or separated shelves keeps risks in check. Regular safety reviews, not just a once-a-year drill, help maintain habits.

In my experience, the best outcomes show up in teams where everyone treats proper storage as part of the job, not a box to tick. Bad storage costs time, money, and sometimes safety. Getting it right rewards everyone with reliable, high-quality material—a win in my book every time.

Octylmethyldiethoxysilane shows up in specialty coatings, adhesives, and sometimes in labs aiming to modify surfaces. In workrooms, I’ve learned chemical safety isn’t just about rules on paper. Every time you handle a bottle, risk rides on your choices. This silane brings hazards that deserve respect. Its vapors irritate airways, and skin contact can leave red, itchy patches. I once saw a careless transfer splash a colleague’s wrist — what followed was a week of discomfort and regret. Stories like this loom large in labs where protective habits shape every shift.

Nobody expects to spill, but planning for problems beats panicking later. At the bench, always grab nitrile gloves, a long-sleeved lab coat, and tight-fitting eye protection. Thin gloves end up permeated by silanes in minutes. I favor splash goggles over basic safety glasses. Closing up every inch of exposed skin reduces risk — no one wins points for getting burned. If ventilation feels off or you're working with large volumes, a chemical-resistant apron or face shield makes sense.

Keep this chemical in tightly sealed containers, far from water, acids, or open flames. Octylmethyldiethoxysilane can react with moisture in the air, forming ethanol and other byproducts that may be flammable. Fume hoods remain a must for transfers and weighing. In my own routine, I line up all materials before cracking the cap, cutting down on distraction and handling time. That habit saved me once during a busy afternoon — no running around, no uncapped bottles left alone.

Spills turn routines upside down — panic hurts more than the chemical in those moments. I’ve watched lab mates freeze and lose time, letting vapors build up. Keep absorbent pads, neutralizing agents, and a proper spill kit ready. If you drop anything, clear the area, throw on a respirator if needed, and clean up right away with all windows open. Bag contaminated towels and gloves for hazardous waste. Never pour this stuff down the drain. Follow your local hazardous waste protocols exactly, or risk fines and environmental damage.

No checklist replaces an aware mind. Before anyone handles octylmethyldiethoxysilane, do a walk-through of the process. I train new people on these chemicals by running real-life drills using water — less panic, more muscle memory. Read the latest safety data sheets before a project, not halfway through. If something spills or exposure happens, don’t brush it off. Visit a wash station, flush affected areas for 15 minutes or more, and get medical advice right away. Peer pressure can help; nobody wants to be the weak link that endangers the group.

Time and again, small choices add up. A lab or plant grows safer when everyone keeps eyes open for leaks, faulty containers, or blocked emergency showers. Supervisors should hold regular refresher sessions and invest in better training. Chemical exposure risks remain hidden until procedures break down. My best workplaces offered open channels for reporting hazards and feedback, making the environment safer for everyone. Building a safety culture starts with simple, repeatable habits — gloves on, goggles tight, mouth shut around fumes. That’s how you keep everyone at work tomorrow.

| Names | |

| Preferred IUPAC name | octyl(methyl)bis(ethoxy)silane |

| Other names |

Diethoxy(methyl)octylsilane n-Octylmethyldiethoxysilane |

| Pronunciation | /ˌɒk.tɪlˌmɛθ.ɪlˌdaɪ.ɪˌθɒk.siˈsaɪ.leɪn/ |

| Identifiers | |

| CAS Number | 18765-38-3 |

| Beilstein Reference | 3657864 |

| ChEBI | CHEBI:87254 |

| ChEMBL | CHEMBL529763 |

| ChemSpider | 20207114 |

| DrugBank | DB11213 |

| ECHA InfoCard | 03e6b52b-0e1a-4c52-8fa3-a122dfbfd502 |

| EC Number | 206-946-9 |

| Gmelin Reference | 803890 |

| KEGG | C18602 |

| MeSH | D000077215 |

| PubChem CID | 116935 |

| RTECS number | GZ3150000 |

| UNII | L3W3D78F7S |

| UN number | UN1993 |

| Properties | |

| Chemical formula | C12H28O2Si |

| Molar mass | 246.43 g/mol |

| Appearance | Colorless transparent liquid |

| Odor | Odorless |

| Density | 0.89 g/mL at 25 °C(lit.) |

| Solubility in water | Insoluble |

| log P | 2.9 |

| Vapor pressure | 0.1 hPa at 20 °C |

| Acidity (pKa) | 13.2 |

| Basicity (pKb) | 13.46 |

| Magnetic susceptibility (χ) | -72.8 × 10⁻⁶ cm³/mol |

| Refractive index (nD) | 1.427 |

| Viscosity | 4 mPa.s |

| Dipole moment | 2.21 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 223.3 J·mol⁻¹·K⁻¹ |

| Std enthalpy of combustion (ΔcH⦵298) | -1566 kJ/mol |

| Pharmacology | |

| ATC code | No ATC code |

| Hazards | |

| GHS labelling | GHS02, GHS07 |

| Pictograms | GHS07 |

| Signal word | Warning |

| Hazard statements | H315, H319, H411 |

| Precautionary statements | P210, P233, P240, P241, P242, P243, P261, P271, P305+P351+P338, P312, P337+P313, P403+P235 |

| Flash point | 62°C |

| Autoignition temperature | 225 °C |

| LD50 (median dose) | LD50 (median dose): Oral, rat: > 2000 mg/kg |

| NIOSH | GVG17250 |

| PEL (Permissible) | PEL (Permissible Exposure Limit) for Octylmethyldiethoxysilane: Not established |

| REL (Recommended) | 3.5 mg/m3 |

| Related compounds | |

| Related compounds |

Octyltriethoxysilane Octyltrimethoxysilane Methyltriethoxysilane Methyldiethoxysilane Triethoxysilane Octylmethyldimethoxysilane |