The story of N-(2-Aminoethyl)-3-aminopropylmethyl-diethoxysilane starts with the growth of organosilicon chemistry after the mid-20th century. Scientists looked for new ways to bring together organic and inorganic materials. This compound grew out of a stream of research focused on the functionalization of silanes. Early industry focused on basic alkoxysilanes for things like adhesives and sealants. As demands increased, companies and labs pushed for molecules that could both bond strongly to silica-based surfaces and react with a wide array of organic compounds. The introduction of diaminoalkyl-functional silanes, particularly with both ethyl and propyl segments, changed the treatment of glass fibers, ceramics, and even some plastics. Process chemists figured out how to control hydrolysis rates and avoid premature polymerization, making these silanes more practical for commercial production and end-users. My early years in the lab were spent learning how the right silane coupling agent made the difference between a bond that lasts and one that fails in a simple humidity test.

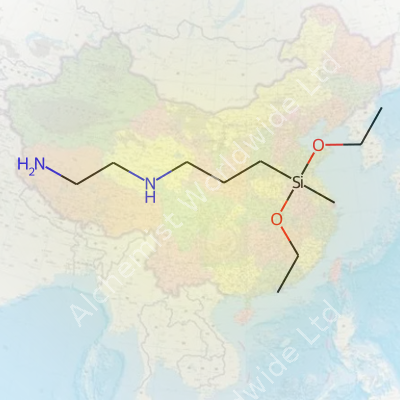

N-(2-Aminoethyl)-3-aminopropylmethyl-diethoxysilane shows up as a colorless or pale yellow liquid, faintly amine-like to the nose. People in coatings and adhesives know it by its chemical reliability and strong reactivity at both the silicon and amine groups. Its backbone boasts two amine groups separated by flexible alkyl chains, topped with two ethoxy silane branches and a methyl group on the silicon atom. This made it valuable in surface modification projects, not just as a laboratory curiosity but as a staple of many commercial primers and crosslinkers. I have worked with this agent for treating glass beads in composite resins, watching as its amine groups improved resin adhesion and resistance to moisture damage. The product’s trade names are many, each belonging to a different supplier, so researchers and buyers must pay attention to actual chemical structure instead of just a label.

This silane remains stable at room temperature, with a boiling point often near 280°C and a moderate vapor pressure, making it manageable without sophisticated containment. Its molecular weight hovers in the mid-200s. It stands out for high miscibility in common organic solvents and fast hydrolysis in water, often generating ethanol and silanols. Its diamino groups contribute to strong reactivity with epoxies, isocyanates, and certain carboxylic acids, while its silane functionality ensures quick bonding to glass and metal oxides. Unlike bulkier silanes or those with only one amine per molecule, this reagent carries a punch in crosslinking and surface reactivity. Anyone who has spilled some will recall the distinct amine smell hanging in the air, a sign of its volatility and the need for careful handling.

Most suppliers grade this material at over 97% assay by GC, listing density at roughly 0.96 g/cm³ and refractive index usually sitting around 1.44. Color is tracked by the APHA scale, commonly below 50. The best bottles carry clear lot numbers and traceability to specific synthesis runs. SDS sheets highlight flash points usually above 100°C, making storage less restrictive than for many other organosilanes. Supplier paperwork calls out amine value ranges and water content, often kept below 0.5% for better shelf life. Over the years, I have learned to double-check labeling, especially since small differences in alkyl chain length or substitution can wildly change surface treatment success.

Chemical manufacturers build this silane by reacting methyl diethoxysilane with N-(2-aminoethyl)-3-aminopropylamine under strict exclusion of moisture. Process engineers often use a catalyst and remove byproducts under reduced pressure, limiting the risk of premature hydrolysis or polymerization. Careful distillation gives the clean final product. Yields approach 80%, sometimes higher on a larger scale. Factories emphasize anhydrous techniques—one stray drop of water can kick off uncontrollable silanization, leading to clogs and lower purities. My own attempts at small-scale synthesis in the university days often faced trouble at the purification stage, where even tiny contaminations could trigger gelling or darkening.

Both the amine portions and the silane portion of the molecule act as sites for reaction. The diamine part forms covalent bonds with epoxy resins, urethanes, and acids, often improving mechanical strength in the end product. The diethoxysilane segment reacts rapidly with moisture on surfaces, forming siloxane bonds. If a formulator needs to introduce more flexibility or a longer chain, standard alkylation reactions or even ethoxysilane substitution let chemists tweak performance. Newer work in surface chemistry explores grafting this silane to nanoparticles or integrating it in sol-gel processes, resulting in improved dispersions and durability. In my experience, the best results stem from keeping reaction conditions precise; overcooking the mix can give unpredictable products or turn it into a gooey mess.

Chemists and buyers see this compound under labels like AEAPTMS, N-aminoethyl-3-aminopropylmethyldiethoxysilane, and even trade names like Dynasylan® or Silquest®. Different suppliers may shorten or modify the name, but regulatory filings specify exact structure routinely. Spec sheets keep CAS numbers prominent, but confusion can still arise if only shorthand or company-specific names show up on paperwork. It always pays to check both the chemical structure and full IUPAC name before making substitutions in a process line.

Amine-functional silanes require solid ventilation, chemical splash goggles, and nitrile gloves. The compound’s low enough volatility avoids the worst inhalation risks, but the amine groups can irritate skin and mucous membranes. Most safety data points to handling this chemical in well-ventilated fume hoods and storing it in sealed, moisture-proof containers. Manufacturers keep emergency showers close, especially when scaling up batch operations. Spills call for absorbent materials and immediate cleanup. Going through these safety routines becomes second nature after a few months on the production floor; cutting corners quickly leads to stinging eyes or worse.

Industrial teams use N-(2-aminoethyl)-3-aminopropylmethyl-diethoxysilane in fiber treatment for composites, paint adhesion promoters, and even as a coupling agent for improving filler-resin compatibility. Electronics manufacturers treat glass surfaces with it prior to resin encapsulation, extending device life and combating humidity. I have seen this silane give better pigment dispersion and shelf stability to high-performance coatings. Research and pilot-scale operations leverage its diamine group to bind with biomolecules, opening the door for hybrid materials useful in sensors and medical diagnostics. Each application brings new technical questions, but the compound’s dual-reactivity frequently leads to breakthroughs.

Academic labs and corporate R&D centers continually probe new uses for this compound. Recent studies track its ability to anchor nanoparticles onto glass, producing anti-fogging and scratch-resistant coatings. Other groups tweak the base molecule to build soft, flexible hydrogels or reinforce 3D-printed materials at the interface. Environmental testing increases too, monitoring how breakdown products interact with wastewater treatment plants. In my case, early research on composite resins led to huge differences in tensile strength based on the choice and amount of this silane, reinforcing the role of basic chemistry in real-world performance.

Toxicologists report moderate acute toxicity, mostly from inhalation or direct skin contact. Animal studies show reversible irritation, so guidelines emphasize glove and eye protection. Regulatory agencies require tracking environmental release, as hydrolyzed byproducts can affect aquatic life. Chronic exposure data remain limited, but no strong links to carcinogenicity or severe organ damage have turned up so far. Proper engineering controls help reduce risk. I have witnessed supervisors drill safety into new hires, sometimes with grim stories of mishaps from similar aminosilanes in the past, grounding hazmat awareness in more than theoretical knowledge.

As hybrid materials and smart surfaces rise in demand, this diaminoalkylsilane seems poised for wider use. New formulations for biomedical patches, next-generation adhesives, and nanomaterial composites rely on its strong reactivity and dual affinity for both inorganic and organic partners. I see increasing efforts to lower residual unreacted silane in the end products, driven by desire for greener, safer consumer goods. Future technical breakthroughs likely arise from tighter control over structure and purity. That focus should reward both process engineers and environmental stewards, giving more performance at lower risk for workers and communities.

A lot of us have seen silanes come up in conversations about coatings and adhesives. N-(2-Aminoethyl)-3-Aminopropylmethyl-Diethoxysilane might sound complex, but this molecule plays a straight-shooting, practical role in how materials get along with each other. Anybody who’s ever tried to paint a metal gate and watched the paint peel knows that getting things to stick together isn’t as basic as it seems. This silane finds its place firmly in surface treatment, bridging the gap between organic polymers and inorganic surfaces like glass, metals, or minerals.

Let’s break down what this chemical does. In manufacturing and research, people rely on silane coupling agents to create a tough bond between materials that normally repel each other. Glass fibers reinforced with resin, for example, need some help getting the polymer to grab hold of the glass. This doesn’t just keep things glued together. It can make a difference in how long a product lasts or how well it stands up to tough weather.

N-(2-Aminoethyl)-3-Aminopropylmethyl-Diethoxysilane brings two key features to the table: it has both silane and amine groups. The silane part attaches tightly to surfaces like silica and metal oxides through chemical bonds. The amine groups provide anchor points for organic polymers like epoxy, polyurethane, or even some silicone products. By forming a sturdy bridge, this silane basically gives a friendly handshake between different worlds—keeping the result from delaminating or crumbling under stress.

These features become crucial in industries focusing on composites. Wind turbine blades, automotive parts, or printed circuit boards all demand tight bonding between filler or fiber and matrix. Silane coupling agents like this one bump up mechanical strength and water resistance. I’ve seen this in practice—fiberglass resin casting in the lab holds up much better with the right surface primer, and that primer is almost always silane-based.

It doesn’t stop at fiberglass. Sealants, coatings, and adhesives benefit from increased adhesion and longer life when they use coupling agents correctly. For example, using this molecule in coatings can help prevent peeling, even after years of exposure to rain and sun. That’s not just theory. Bridge repairs, boat construction, and electronics manufacturing see measurable improvements. Tensile strength, impact resistance, and moisture protection all tick up nicely once surfaces get the right treatment.

Working with silanes takes a bit of care. Vapors can irritate skin or lungs if you’re not wearing gloves and proper ventilation isn’t in place. Waste handling also needs to stay responsible, as with any specialty chemical. Companies spend real effort keeping employees safe and sticking to safety data sheets.

The impact of N-(2-Aminoethyl)-3-Aminopropylmethyl-Diethoxysilane gets bigger as industries seek tougher, lighter, more efficient materials. Sustainable design means products have to hang together for the long haul, not just look good on day one. Pushing for higher standards in surface preparation and chemical selection leads to less waste and fewer repairs down the line, a win for both business and the environment.

Better training on chemical handling and open sharing of test data can help reduce trial-and-error in new product development. More collaboration between chemical suppliers and end-users often brings safer, more reliable results. Creating user-friendly kits for field applications can also help bring advanced bonding technology beyond big factories into smaller shops or construction sites.

Every time I open up a box from the warehouse, I check for signs of moisture. It sounds simple, but even a little dampness can ruin a whole batch of product. Plenty of people have lost trust in companies just from a box that smelled off, or bottles caked with dust. I’ve seen customers post pictures online, tearing down months of hard work over something that could have been avoided with a better storage plan.

Over the years, I’ve learned that room temperature is not the same for everyone. One summer, a shipment sat too close to a window in direct sunlight. By the time the box arrived, half the contents had separated or started to break down. Some ingredients turn into goop. Medicines lose their strength. Food spoils within hours. That’s money down the drain—and often a safety risk.

Lighting wrecks havoc, too. Some chemicals and supplements break down when exposed to light, turning cloudy or yellow. You need a cool, dry cupboard or a dedicated fridge. Most folks try to cut corners with storage space, but short-term convenience becomes a long-term headache. I’ve helped small teams who lost inventory just because someone stashed bottles above a boiler room.

Every product deserves its own spot—and that usually means clear labeling. Jars, cartons, even pails—everything needs its own label, date, and batch code facing forward. Precision matters. Last year, a friend of mine in the bakery business mixed up two bags of flour, one regular and one gluten-free, just because nobody updated the stickers. The bakery spent the next week recalling orders and refunding clients.

Stable temperatures beat fancy gadgets. I use a good old thermometer to keep an eye on the room, not a smartphone app that only updates once in a while. Typical ranges: 15-25°C for most dry goods, and 2-8°C for temperature-sensitive ones—straight into the fridge, never near the door where teens open and close it a dozen times an hour.

Moisture kills quality. I always store dry ingredients away from sinks and windows. I choose airtight containers for powders. For liquids, upright bottles with tight caps—no exceptions. Lost a whole drum of syrup once just because one lid was loose.

Keep things off the floor. Pallets protect from puddles and pests. Shelf organization lets you rotate stock, so you don’t find a forgotten box three years past its prime. At home, it’s easy to push cans to the back, but in business, every old item comes back to haunt you.

You can have the best labels in the world, but if nobody pays attention, product gets wasted. I always run hands-on walkthroughs, showing how to handle and store each type of setup. It’s not glamorous, but it’s the only way to build real trust with clients and keep shipments from spoiling before they even leave the warehouse.

There’s always something to fix. I’ve seen digital logs catch temp spikes that a person would miss. I see value in a quick weekly storage audit—just walk around, open boxes, and check every section. Problems start small, but so do solutions. Strong storage and careful handling don’t just protect products—they protect reputations, and in my book, that’s worth every effort.

Chemicals with names longer than some street addresses tend to rattle nerves in the workplace. Folks who work with N-(2-aminoethyl)-3-aminopropylmethyl-diethoxysilane often ask about hazards, and the question isn't out of place. Even on a good day, trying to pronounce that mouthful while donning goggles is a reminder that chemistry rarely takes lunch breaks.

I remember my own days in the lab, flipping through safety data sheets for every new liquid or powder that made its way onto our shelves. One thing stands out with this compound: the need for cautious respect. It’s a colorless, almost clear liquid that’s often used in surface treatments or as an adhesion promoter for plastics, glass, or ceramics. Like many organosilanes, it doesn't announce its hazards loudly, but it does demand your attention.

Contact with eyes or skin can lead to irritation—think redness, watering eyes, stinging, or dry, cracked hands after a few careless splashes. Respiratory issues aren’t unheard of when vapors hang around in stuffy rooms. Exposure can sneak up in poorly ventilated workshops, where these vapors drift along air currents you can’t see or feel. Swallowing even a small amount could push someone straight to the hospital, and regular inhalation ups the stakes over time.

Many businesses see chemicals like this as routine—just another checkmark on the list. Experience says things get dangerous the moment comfort sets in. I’ve seen skilled hands skip gloves because nobody’s watching. That tiny shortcut can turn into costly medical bills or lost workdays.

Long sleeves, chemical-resistant gloves, and splash-proof safety goggles form the holy trinity for hands, eyes, and skin. Companies that set up eye-wash stations close to workbenches show their teams that they care more than just ticking off boxes for inspectors. Good ventilation, proper fume hoods, and training everyone on what to do if chemicals get loose are worth every dollar spent.

Official sources like the European Chemicals Agency (ECHA) and the U.S. chemical safety regulators list this silane as harmful in concentrated quantities. Anyone working with it ought to know that its safety label isn’t there for decoration. Just a quick slip can turn into a real mess.

SDS data tells us it isn’t likely to blow up or burn easily, so fire risk isn't at the top of the threat list. Still, any spill should be wiped up with respect—no sweeping it under the rug. Clean-up kits stocked with absorbent pads and neutralizers help prevent accidents from ballooning into emergencies.

Routine refreshers on chemical handling keep habits sharp. Supervisors walking the floor and pitching in do more for the safety culture than a dozen warning posters. Reporting close calls, swapping stories about near misses, and treating questions about safety as signs of a healthy team makes more sense than blaming mistakes.

Planning for chemical shipments, storage, and disposal needs real attention. Training the crew on emergency contacts, and knowing which hospitals are prepared for chemical exposure, rounds out the best defense. Not every business has a safety officer, but every worker benefits from a boss who asks “Are you sure you’re ready for this?” before the first cap comes off a bottle.

Every compound starts with a formula—a brief code that hints at the arrangement of atoms inside. Chemists see more than just letters and numbers; they see relationships, function, and potential. Ask what a molecular formula tells you, and you’re digging into the core of chemistry itself, where curiosity drives discovery and even subtle changes can rewrite a chapter in science.

Molecular formulas use plain symbols to describe the count and type of atoms in a molecule. Take glucose: C6H12O6. This means six carbons, twelve hydrogens, and six oxygens form one of biology’s favorite sugars. Each letter and digit sketches the beginning of a much larger picture. Without these formulas, quality control in food, pharmaceuticals, and energy wouldn’t work.

Seeing a formula is different from knowing the arrangement. C2H6O, for example, can be ethanol—the alcohol in beer—or dimethyl ether, a gas with totally different uses. The formula alone won’t explain taste or toxicity. It starts the conversation—just the tip of the iceberg. Good researchers ask: What does the structure look like? How does it behave?

Structure speaks louder than formulas. One arrangement might bend into a ring, another might stretch into a line, although both share the same atoms. Benzene, C6H6, became the backbone for much of modern chemistry. Its unique ring shape, with alternating double bonds, explained strange patterns in dyes, medicines, and fuels. Without cracking this code, industries might have stayed stuck with older, less effective products.

Structure isn’t just for academics. It makes a difference in medicine cabinets and manufacturing floors. My own first brushes with chemistry involved trying to draw structures next to formulas and puzzling out why aspirin eased headaches, yet similar compounds did nothing. That extra line or twist in the shape alters how molecules fit into living cells or slide into engines.

History shows what can go wrong when people mistake one structure for another. Thalidomide, a sedative in the 1950s, tragically revealed that two compounds with the same formula can split into very different effects—one safe, one harmful. These lessons drive home the need for accuracy at every step, from classroom labs to global supply chains.

Understanding both formula and structure isn’t just academic. Makers of chemicals face tight rules. The EPA, FDA, and other agencies flag certain formulas to stop pollution or protect health. Only by clarifying structure can companies meet these standards. Supply chain transparency counts on companies tracking what, exactly, goes into every batch.

Real solutions take education seriously. Students and workers learn not just how to balance equations, but how to visualize bonds and angles. Open databases, like PubChem and ChemSpider, let everyone look up structures, formulas, and hazard data. Experienced chemists use 3D models and digital tools to avoid dangerous mix-ups or wasted ingredients. Responsible manufacturing means double-checking every ingredient’s real identity, not just what’s printed on the label.

Following the trail from molecular formula to structure sparks careful research, tighter safety, and smarter innovation. The next time a question about a compound’s identity comes up, taking a deeper look at both formula and structure protects everyone, from the researcher to the consumer.

Chemists and formulators always look for ways to create stronger, longer-lasting bonds between different phases in composites, coatings, or adhesives. Silane coupling agents play a key role. Some folks like to mix and match different silanes, hoping to hit the sweet spot between cost, performance, and processability. It sounds like the right approach, but mixing these compounds isn’t as simple as tossing them together and hoping for the best.

I spent plenty of time in labs chasing toughness in filled resins and water resistance in construction adhesives. Every time we tried combining two or three types of silane, we saw odd things if the chemistry wasn’t in sync. Epoxy-functional silanes can boost the bond between glass and epoxy matrices. Amino-functional silanes contribute to adhesion in mineral-filled polyolefins. Not all silanes cooperate, though. Trialkoxysilanes and organofunctional silanes don’t always form a truce, especially in water-based systems.

Silane coupling agents use hydrolyzable alkoxy groups to graft onto surfaces, like glass or mineral fillers. Their organofunctional groups interact with the matrix, like polyurethane or epoxy. The problem starts if one silane’s hydrolysis outpaces the other. Fast-reacting amino silanes might polymerize before the slow-reacting partner finds its mark. You can end up with wasted material, unpredictable surface coverage, and—worse—a drop in final strength.

The data backs this up. I’ve seen research from the Journal of Adhesion Science and Technology showing that blends of vinyl and amino silanes sometimes compete on the same surfaces rather than complement each other. This competition leads to incomplete surface coverage, or even desorption over time. You get unpredictable performance on the jobsite or the factory floor.

Consulting with trusted suppliers gives you the right chemical composition and performance data. Reliable producers document the compatibility of their silanes with established standards—ASTM C794 or ISO 8339 for adhesion, for example. Backed by transparent data, you know what you’re getting.

Using high-purity, pre-formulated silane blends increases success rates. Mixing raw silanes just before processing leaves too many variables unaccounted for—moisture in the air, inconsistent pH, impurities in base materials. A pre-tested blend eliminates these headaches. I’ve seen big differences in line uptime and batch consistency just by swapping out raw mixtures for certified blends.

Start with a targeted approach. Identify what you want—a stronger bond to silica, better flexibility at cold temps. Don’t just blend two silanes and hope they bring the best of both worlds. Check for chemical compatibility. Look for published case studies from manufacturers who willingly show side-by-side application data and FTIR spectra. Stay skeptical about generic advice from distributors without technical backing.

Keep an eye on real-world trial results. The final answer on compatibility isn’t always on the label or in the data sheet. Run small pilot batches, test for moisture stability, run accelerated aging. In my experience, these real-life checks catch hidden pitfalls, like haze or early debonding, that theory alone can’t predict.

Mixing silane coupling agents isn’t forbidden, but it demands a clear understanding of chemistry and performance. Rely on solid evidence, look for experience-based recommendations, and don’t skip pilot evaluations. With this approach, professionals set up their formulations for lasting reliability and end-user trust.

| Names | |

| Preferred IUPAC name | N-[3-(Diethoxy(methyl)silyl)propyl]ethane-1,2-diamine |

| Other names |

N-(2-Aminoethyl)-3-aminopropyl(methyl)diethoxysilane AEAPMDES Diethoxy(methyl)[3-(2-aminoethylamino)propyl]silane 3-(2-Aminoethylamino)-N-methylpropyl(diethoxy)methylsilane 3-(2-Aminoethylamino)propylmethyldiethoxysilane |

| Pronunciation | /ɛn-tuː-əˈmiːnoʊˌɛθɪl-θriː-əˈmiːnoʊˌproʊpɪlˈmɛθəl-daɪˌɛθɒksɪˌsaɪleɪn/ |

| Identifiers | |

| CAS Number | 104316-82-9 |

| Beilstein Reference | 1840563 |

| ChEBI | CHEBI:148483 |

| ChEMBL | CHEMBL4294095 |

| ChemSpider | 13870480 |

| DrugBank | DB13821 |

| ECHA InfoCard | 03-2119980174-46-0000 |

| Gmelin Reference | 107207 |

| KEGG | C18606 |

| MeSH | C08-F07-H13 |

| PubChem CID | 77501868 |

| RTECS number | UB2975000 |

| UNII | V917G8QK0Y |

| UN number | Not regulated |

| Properties | |

| Chemical formula | C10H26N2O2Si |

| Molar mass | 276.47 g/mol |

| Appearance | Colorless to light yellow transparent liquid |

| Odor | Amine-like |

| Density | 0.96 g/mL at 25 °C (77 °F) |

| Solubility in water | soluble |

| log P | -0.9 |

| Vapor pressure | <0.01 hPa (20 °C)> |

| Basicity (pKb) | 6.59 |

| Magnetic susceptibility (χ) | -80.0·10⁻⁶ cm³/mol |

| Refractive index (nD) | 1.449 |

| Dipole moment | 2.58 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 561.8 J/mol·K |

| Pharmacology | |

| ATC code | '' |

| Hazards | |

| Main hazards | May cause respiratory irritation. Causes skin irritation. Causes serious eye irritation. |

| GHS labelling | GHS02, GHS07 |

| Pictograms | GHS05,GHS07 |

| Signal word | Warning |

| Hazard statements | H302 + H319 + H314 |

| Precautionary statements | P261, P280, P305+P351+P338, P337+P313 |

| Flash point | 82 °C |

| Autoignition temperature | Autoignition temperature: 245 °C |

| LD50 (median dose) | LD50 (oral, rat) > 2000 mg/kg |

| NIOSH | NA |

| PEL (Permissible) | Not established |

| REL (Recommended) | REL (Recommended): 5 ppm (mg/m3) |

| Related compounds | |

| Related compounds |

N-(2-Aminoethyl)-3-aminopropyltrimethoxysilane N-(2-Aminoethyl)-3-aminopropyltriethoxysilane 3-Aminopropyltriethoxysilane N-(2-Aminoethyl)-3-aminopropylmethyldimethoxysilane |