Vinyltrichlorosilane’s background stretches back to early silicon chemistry exploration. Researchers poked at the boundaries of silane compounds, driven by a practical goal: finding ways to stick organic and inorganic worlds together. In the twentieth century, the pace picked up as industry sought new materials for electronics, sealants, and coatings. It was right here that vinyltrichlorosilane found its groove, powering a range of surface treatments and functional silicone polymers. As manufacturing ramped up after WWII, vinyltrichlorosilane became a backbone for cross-linking reactions that reshaped everything from semiconductor technology to automotive manufacturing, proving how a reactive monomer could ripple through entire markets.

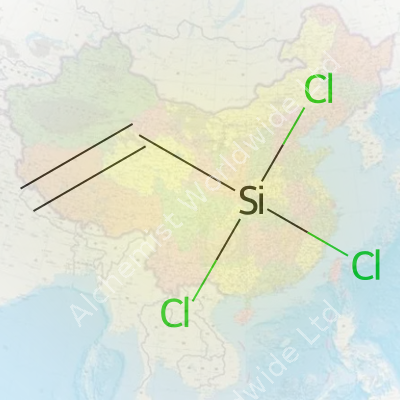

Vinyltrichlorosilane has an unmistakable acrid smell and comes as a colorless to yellowish liquid. Beyond its sharp odor, it’s got a reactive vinyl group hanging off one side and three hungry chlorine atoms on the other, making it a handy chemical bridge. Folks in labs and factories find value in how it brings surfaces and siloxane chains together, building strong bonds with glass, metal, and ceramics. It doesn’t just sit on the shelf – it gets churned into silicones, resins, and treated fillers, making it a hidden hand behind waterproof coatings, adhesives, and toughened plastics.

This liquid has a boiling point close to 92°C and keeps a respectable distance from water, promptly hydrolyzing with a hiss. It’s lighter than water, showing a density near 1.19 g/cm³, and vapor pressure is not something you can ignore around room temperature, as it evaporates and irritates eyes and lungs. Armed with a vinyl group, it opens the door for addition reactions. Three chlorines make it ready to swap partners, tossing out HCl when it meets even a sip of moisture. Vinyltrichlorosilane doesn’t hang around outdoors, breaking down under sunlight and air. So, storage means tightly capped containers and careful attention to temperature swings.

Bottles land on the shelf stamped with purity levels, often above 98%. Labels spell out hazard codes, proper UN numbers (like UN1305), and signal phrases that cut right to the point: “Corrosive” and “Flammable.” Safety datasheets demand chemical goggles, acid-resistant gloves, and proper ventilation. In my experience, one sniff near the cap will tell you this is no plaything. Even small spills etch glass and attack metals, so folk in warehouses and labs keep spill kits ready and treat every bottle with a kind of wary respect. Suppliers guarantee certificates of analysis, showing not just main compound levels but tight controls on water content and unwanted siloxanes.

Manufacturers cook up vinyltrichlorosilane by reacting acetylene with trichlorosilane in the presence of copper or platinum catalysts. The chemistry doesn’t demand exotic ingredients but does require careful attention to temperature, pressure, and catalyst-handling skills. Some big plants rely on fluidized bed reactors, keeping conditions tightly dialed to maximize yield. Byproducts like dichlorosilane and silicon tetrachloride emerge, so separation columns and distillation towers become workhorses, refining the product to spec. Old research journals lay out tweaks and tricks, but scale-up brings its own headaches, from heat management to disposing of acidic waste streams.

Vinyltrichlorosilane loves to react with moisture, releasing hydrogen chloride and building siloxane networks in the blink of an eye. Any chemist handling it soon realizes you can’t leave a flask open long; water vapor will ruin a batch. The vinyl group, on the other hand, welcomes radical-initiated additions – think about introducing new side chains or polymerizing with other vinyl monomers to give tailored siloxanes. The trichlorosilyl end links with glass fibers or metal oxides, strengthening adhesives and boosting the performance of composites. Industrial chemists tweak reaction temperatures, solvent choice, and reactor materials to coax the most out of each batch, always chasing purity and performance.

On chemical shelves, you’ll spot names like trichlorovinylsilane, VTS, or Silane, trichlorovinyl-. Brand names pop up: some from American giants, others from European suppliers, always with subtle differences in packaging or purity claims. Regardless of label, most users talk about vinyltrichlorosilane’s role instead of its name, calling it “the coupling agent” or “that crosslinker.” For folks juggling multiple suppliers, the list of synonyms keeps procurement from missteps, ensuring what arrives in the drum matches what engineers need.

Knowing the hazards shapes every rule about this stuff. Splashing a drop means chemical burns, so full-face shields and chemical aprons become everyday wear. Storage happens under dry nitrogen where possible, away from acids, bases, and anything that can ignite. Engineers build in extraction hoods and train every new technician to treat containers as if a fumble will run everyone out of the building. In my own time around silanes, spill drills and proper glove removal feel just as essential as batch tracking. Regulations from OSHA, REACH, and other agencies require employee training and tight controls over emissions and effluents, driving improvement in everything from warehouse design to emergency response plans.

Vinyltrichlorosilane’s true power shows up in materials science. Manufacturers use it as a silanization agent to modify surfaces, especially in the glass and fiber industries. Adding it to glass fibers boosts adhesion in thermosetting resins for circuit boards, high-pressure tanks, and automotive parts. Adhesive makers blend it into sealants for better binding strength, longer life, and weather resistance. Paint companies sneak it into water-resistant coatings, while rubber producers turn to it for toughening silicone elastomers. Electronics demand it for treating semiconductor wafers or prepping surfaces before transistor and diode fabrication. In every case, whether bonding an aircraft windshield or sealing a microchip case, this chemical shows practical value with strong results.

Chemists keep digging for deeper performance, better environmental safety, and broader applications. Academic labs chase next-generation siloxane networks aimed at aerospace and biomedicine. As the microelectronics industry seeks flatter, more robust coatings, researchers experiment with vinyltrichlorosilane’s polymerization chemistry. Plastics companies collaborate with universities, looking for clues on reducing residual chloride or incorporating bio-based monomers. Industry standards are tough and getting tougher, so R&D teams approach every batch like a new puzzle, honing production to cut waste and energy use. Journals fill up with fresh patent filings and novel composite designs boosted by just a few drops of well-tuned silane.

Vinyltrichlorosilane doesn’t get a free pass from health and safety watchdogs. Studies pin down corrosive effects on skin, eyes, and the lungs. Acute exposure to vapors brings coughing, shortness of breath, and sometimes lasting damage. Chronic, low-level inhalation links to bronchitis and airway irritation, so monitoring air quality in processing rooms matters. Toxicologists track breakdown products, especially hydrogen chloride, noting their risks in confined or poorly-ventilated spaces. Animal studies flagged risks but real protection comes from simple, direct actions: careful handling, use of personal protective gear, and strong local exhaust systems. Regular risk assessments and first-aid training help limit injuries and keep long-term workers healthy.

The march toward advanced composites, lighter vehicles, and tougher electronics keeps demand for smart coupling agents strong. Vinyltrichlorosilane remains a go-to tool for surfaces that need to stay bonded under punishing conditions: rain, salt, vibration, or years of weathering. Environmental rules push for cleaner synthesis and less hazardous byproducts, nudging researchers toward new catalysts and recyclable solvents. Green chemistry principles continue to shape production, and high-throughput automation promises faster discovery of new vinyl-functional silanes. What worked for adhesives and semiconductors yesterday could pivot toward biomedical coatings or flexible solar panels tomorrow, proving that this classic compound still has plenty of tricks left—if researchers and manufacturers keep pushing creative chemistry.

Vinyltrichlorosilane is not a household name, but its fingerprint is everywhere. This chemical pulls more than its weight in the worlds of construction, electronics, and advanced materials. Anyone who has handled adhesives, coatings, or certain electronics has likely benefited from its unique talents. I remember working in a lab where we tested water-repellent treatments for brick and concrete. Vinyltrichlorosilane played the starring role in those solutions. It transformed dull, porous surfaces into tough, waterproof ones that stood up to heavy rains.

Chemists look to vinyltrichlorosilane because of the way it attaches to glass, metals, and ceramics. After all, most surfaces do not naturally bond well with paints or adhesives. This compound acts like a bridge. Its vinyl group sticks to organic polymers, like those in silicone rubber, while the chloride groups react strongly with inorganic surfaces. The end result: a tight, reliable connection that helps products last through harsh weather or heavy use.

It’s easy to overlook how much this matters in real life. Take windshields, for example. Without a good primer, glass resists adhesives, making it hard to keep the glass in place for years. Vinyltrichlorosilane gets into the microscopic nooks and crannies, locking everything together. Whether it’s car windows or touchscreens, this invisible helper keeps things from falling apart.

The silicon industry has boomed, especially as gadgets become smarter and energy-saving tech gets popular. A report by MarketsandMarkets estimated the global silicone market crossed $18 billion a year, partly thanks to compounds like vinyltrichlorosilane. Construction sites eat up huge volumes for weatherproof coatings. Electronics makers crave its reliability for circuit boards and displays. Even agricultural firms treat soils and greenhouses with specialized coatings based on this chemistry.

With all this growth, managing risks jumps to the forefront. Chlorosilanes can burn skin, irritate lungs, and release hydrochloric acid if handled carelessly. I remember safeguarding my lab bench with extra gloves and face protection, triple-checking every stopper and valve. Companies cannot skip training or cut corners on safety protocols—doing so endangers workers and neighborhoods alike.

Scientists have started looking for ways to keep the strengths of vinyltrichlorosilane, while easing up on the dangers. Some labs now cook up modifications that swap aggressive chlorides for safer groups. Others tighten recycling practices, capturing stray fumes and leftover liquids before they find their way outside the factory gate. Regulations tighten every year, pushing the industry to rethink old habits.

Vinyltrichlorosilane proves that big breakthroughs in materials science do not always grab headlines, but make daily life smoother and safer. As companies keep up with demand, the most responsible choose solid safety policies and smarter chemistry. By improving these processes, factories can keep turning out high-performance materials—without putting health or the environment at risk.

I’ve worked on floors where someone cracked open a bottle of Vinyltrichlorosilane and a dozen pairs of eyes turned to see if it fumed. With chemicals this reactive, the difference between a regular day and a trip to the hospital comes down to practice and respect for the rules. Vinyltrichlorosilane, a clear liquid with a sharp smell, reacts with water to give off hydrochloric acid. It burns skin, damages lungs, and can clear a room quicker than a fire alarm.

Every safety training I’ve ever sat through has hammered one thing home: Gear up or get hurt. With Vinyltrichlorosilane, skipping gloves, goggles, or a proper face shield means gambling with your eyes and lungs. Nitrile or butyl rubber gloves give you real protection. Standard safety glasses don’t cut it on their own. Splash goggles and a face shield stop accidents that can turn into lifelong injuries. A respirator with a filter rated for acid gases sits on my shelf for a reason—it works. No one walks into a lab with just surgical masks and hopes for the best, not with this stuff.

Handling reactive chemicals never happens alone. If someone in the room doesn’t know what to do in an emergency, that’s an accident waiting to happen. That’s why I make sure everyone checks the signage and knows where to find the nearest eyewash and shower. One guy on my shift kept a dedicated spill kit labeled “For Vinyltrichlorosilane Only.” Granulated calcium carbonate and absorbent pads kept in an airtight box turned leaks from a nightmare into a quick, controlled cleanup.

Vinyltrichlorosilane fumes irritate at best and devastate at worst. I can smell hydrochloric acid from a spill before my brain processes anything else. That’s why a fume hood or a well-ventilated glovebox becomes a non-negotiable part of working with this liquid. No open vessels outside of a hood, no decanting into anything that isn’t acid-resistant, and always a spotter who knows how to use the emergency cut-off switches.

Storing this chemical means keeping it dry, sealed tight, and away from water. Rusted caps, sweating bottles, or overcrowded shelves threaten more than just the inventory. I always relabel anything that’s not clear and double-check the shelf life. Secondary containment trays and explosion-proof cabinets turn a routine storage job into a safety net against accidents. Simple habits, like buddy checks and consistent lighting, stop disasters before they start.

Even after a hundred dry runs and checklists, every chemist has faced a spill or a break. I grabbed a co-worker by the collar once as he reached for the wrong neutralizer. Bleeding eyes and choking throats don’t fade from memory. Calcium carbonate powder neutralizes spills, not water. Water reacts and releases acid gas. Emergency procedures, rehearsed and drilled, cut the chaos by half.

You learn to respect chemicals after you’ve seen what happens when basic safety is ignored. I’ve known smart people who didn’t make it home because a shortcut seemed harmless. Knowing the science behind Vinyltrichlorosilane’s dangers helps, but discipline on the floor saves lives. No job or timeline justifies risking your skin, sight, or lungs. Safety with reactive chemicals like this rests on learning from those who went before and never letting your guard down.

The chemical formula of vinyltrichlorosilane is C2H3SiCl3. On paper, it looks like just another combination of carbon, hydrogen, silicon, and chlorine. In the lab and out in industrial spaces, this simple formula opens up a world of possibilities. The vinyl group (C2H3) brings reactivity, while three chlorine atoms bonded to silicon allow this compound to act as a bridge in creating materials with unique properties. Silicon-based chemistry often fuels modern industries, and vinyltrichlorosilane ranks high on the list of essential silane compounds.

Most folks never see vinyltrichlorosilane up close. Yet, the effects trickle into plenty of daily encounters. Silicones in electronics, sealants, water repellents, and coatings start off with base chemicals like this one. Vinyltrichlorosilane works as a starting point for functionalized silicones. In my professional science days, I watched how its vinyl group allowed further chemical reactions, setting off chains that end in stable, purpose-built materials.

Getting the formula correct isn’t just an issue of paperwork. Take a mistake in the lab: confusing vinyltrichlorosilane (C2H3SiCl3) with a different trichlorosilane would ruin a batch, wasting both expensive raw chemicals and time. Major industries build expensive process lines for compounds like this. The stakes run high, covering safety, economy, and efficiency.

Knowledge isn’t just power, it keeps people healthy. Vinyltrichlorosilane reacts violently with water, producing hydrochloric acid fumes, which pose a direct lung hazard. That clear formula, C2H3SiCl3, signals the right precautions to take. In past lab work, I learned to handle such chemicals beneath fume hoods, wrapped in gloves and goggles, keeping water sources far away. Real stories about splashes, poor storage, or careless handling sharpen respect for both the science and practice behind industrial chemistry.

Manufacturers rely on vinyltrichlorosilane because it attaches organic groups to silicon frameworks. This trick gives rise to hybrid materials, blending flexibility with water-resistance. Whether producing weather-resistant caulks, smooth cable insulation, or toughened glass, it all circles back to that formula—where three chlorines on silicon imbue extreme reactivity, and the vinyl group opens the door for varied chemistry.

Many accidents could be prevented by clarity. Education in schools, on the production line, and among scientists should not just touch on rote memorization. Real-world drills, hands-on experience, and up-to-date information go further. I remember moments where clear explanations about compounds like vinyltrichlorosilane, not just their formulas but their real dangers and applications, saved headaches and avoided costly lab mistakes. Facilities benefit from digital tracking and well-marked storage areas—not just in writing, but as habits in daily operations.

Vinyltrichlorosilane might sound niche, but its impact stretches across industries and lives. The formula, C2H3SiCl3, symbolizes not just a molecule, but a connection between deep science and everyday experience. Treating chemical knowledge as essential, hands-on, and practical ensures a safer, more productive future for scientists and industry alike.

Vinyltrichlorosilane comes with serious risks. This isn’t just another lab chemical. Anyone handling it knows the sharp odor, the way vapors start to bite at your nose, and the uneasy feeling of a single splash. One bump to a bottle left where it shouldn’t be, and fumes hit the air. A quick reaction matters. But none of that matters if storage fails.

One time, I walked into a storage room on a summer day, and the heat hit me like a wall. That room barely kept to the rules. A faded “flammable” sticker hung on a half-open cabinet. More than one container of vinyltrichlorosilane sweated in the damp air. You could say rules were being followed, but nobody there truly respected how nasty this stuff can get.

This chemical reacts fast with water, giving off hydrogen chloride gas. Even tiny spills turn humid air into an acid fog. Vinyltrichlorosilane can damage skin, lungs, and building infrastructure. That’s the reality workers face, from industry to research labs. The issue isn’t just about safety paperwork. It’s about every person who might walk by, not knowing what’s inside the drum or cupboard.

Two things have always mattered in places where people work safely: smart planning and respect for what you’re dealing with. Keep vinyltrichlorosilane containers tightly sealed in a cool, dry place. Temperature swings and moisture are threats. I make sure storage rooms hold steady below 25°C, far from sunlight or heat sources. Humidity stays low, and I never store water-reactive chemicals below plumbing or sprinkler lines. A cabinet designed for flammable liquids works, but only if it sits dry, far from acids and bases. Once, a small leak above a storage cabinet made everything inside useless. That mistake stuck with me for years.

Labels save lives. It sounds simple because it is. Use clear labels with the chemical name and hazards, and keep an up-to-date inventory nearby. It helps a lot in emergencies. I’ve seen young staff open a mystery container because someone got lazy with tape and a marker. Training stops these mistakes. Anyone who handles or works near vinyltrichlorosilane should know its risks and emergency steps. That means regular drills, clear procedures, and easy access to data sheets. Safety showers and eyewash stations should sit no more than a quick dash away. If you can’t get to one in ten seconds, that’s too far.

Vinyltrichlorosilane will chew through glass if moisture gets in. Always stick with tightly sealed containers made from compatible materials, like certain plastics. Don’t ever transfer into makeshift bottles or recycled jugs. Once, someone used an old soda bottle for a transfer job, and it ended with a near explosion—no professional ever forgets a scare like that.

It’s tempting to cut corners, especially in crowded, budget-pressed labs or warehouses. Truth is, shortcuts put communities and workers in danger. Local environmental laws back up these points: locked storage, spill kits close at hand, and waste handled by certified specialists. One accident can make headlines for all the wrong reasons. Respect for storage rules isn’t just about luck or ticking boxes. It’s about people making it home safe every day.

Vinyltrichlorosilane sounds like another tongue-twister from the chemistry lab, but this sharp-sounding name belongs to a pretty unforgiving substance. You see, this compound loves to react — and not in a polite, quiet way. Spill a little on a wet shop floor or let a bottle sit open in a humid room, and it gets busy. Instead of simply evaporating, it releases hydrogen chloride gas. Folks working in manufacturing or research know this gas brings stinging eyes, harsh coughing, and if you’re not quick about it, serious lung injuries. I remember a friend from my university days who picked up a leaking bottle, oblivious to the invisible plume. His gloves practically melted, and he missed two weeks of class with chemical burns.

Vinyltrichlorosilane isn’t content just to make a mess on your skin. It chews right through, leaving chemical burns that bubble and blister. If you breathe in its vapors, the lungs take the beating. Even a short puff can bring on a wheeze, shortness of breath, or bleeding deep inside your airways. Hospital visits for exposure aren’t rare — OSHA and the CDC have flagged these health problems many times. They warn about its corrosive punch, especially to anyone stuck cleaning up spills without proper protection.

It might not look dangerous at first glance, but vinyltrichlorosilane brings serious fire hazards. A spark in the wrong place, and suddenly there’s a fire throwing out choking hydrochloric acid vapors. Regular extinguishers can make things worse, since water triggers even more dangerous reactions. As a student working in a polymer lab, I watched a benchtop fire cook off with this chemical — the teachers ran for the special gear, not the ordinary fire blankets. The lesson: inexperience and short cuts add to the list of risks.

Vinyltrichlorosilane doesn’t just threaten people. Spills outside the building mean local waterways pay the price. Mixed with water in storm drains or streams, it releases hydrogen chloride and other compounds toxic to fish and plants. Emergency response crews train for this, using special absorbents and neutralizers. Without the right action, contamination spreads far beyond the worksite.

Keeping this chemical in control requires sharp focus. Ventilation systems need regular checks, so any leaks head outside, not straight to workers’ lungs. Employees should suit up with acid-resistant gloves, goggles, and heavy aprons — the disposable stuff won’t block this chemical. Instead of tap water washes, facilities should post calcium gluconate gel stations and chemical-specific first aid. Factories and labs should run regular real-life drills, not just pass around a sheet of rules. Smart storage matters, too: keep it in sealed, labeled bottles, away from moisture and incompatible chemicals, never in a cluttered cabinet.

No one heads to work hoping for a lab accident. Vinyltrichlorosilane brings out the worst in bad routines or ignored warnings. Every mishap spills trouble onto people, property, and the planet. Taking it seriously means going beyond the basics and checking routines, protective gear, and emergency plans. That’s what stops a workday from turning into disaster, and it keeps everyone heading home safe.

| Names | |

| Preferred IUPAC name | Ethenyltrichlorosilane |

| Other names |

Trichlorovinylsilane Vinyltrichlorosilane Vinylsilicon trichloride Trichloro(vinyl)silane |

| Pronunciation | /ˌvaɪ.nəlˌtraɪˌklɔːr.əˈsaɪ.leɪn/ |

| Identifiers | |

| CAS Number | 100-64-1 |

| Beilstein Reference | 635956 |

| ChEBI | CHEBI:51710 |

| ChEMBL | CHEMBL185492 |

| ChemSpider | 60833 |

| DrugBank | DB14583 |

| ECHA InfoCard | ECHA InfoCard: 100.003.875 |

| EC Number | 200-911-5 |

| Gmelin Reference | 80853 |

| KEGG | C19873 |

| MeSH | D014738 |

| PubChem CID | 65332 |

| RTECS number | YV9625000 |

| UNII | XGE1791N06 |

| UN number | 1305 |

| Properties | |

| Chemical formula | C2H3Cl3Si |

| Molar mass | 161.98 g/mol |

| Appearance | Colorless to yellowish liquid |

| Odor | Pungent |

| Density | 1.23 g/mL at 25 °C (lit.) |

| Solubility in water | Reacts |

| log P | 1.7 |

| Vapor pressure | 10 mmHg (20°C) |

| Acidity (pKa) | 1.3 |

| Basicity (pKb) | 13.6 |

| Magnetic susceptibility (χ) | -53.0e-6 cm^3/mol |

| Refractive index (nD) | 1.396 |

| Viscosity | 0.44 cP (20°C) |

| Dipole moment | 1.55 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 274.1 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -363 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -1343 kJ·mol⁻¹ |

| Pharmacology | |

| ATC code | V04CX17 |

| Hazards | |

| GHS labelling | GHS02, GHS05, GHS06 |

| Pictograms | GHS02,GHS05,GHS07 |

| Signal word | Danger |

| Hazard statements | H226, H301, H314, H331, H335, H410 |

| Precautionary statements | P260, P261, P264, P271, P280, P301+P330+P331, P303+P361+P353, P304+P340, P305+P351+P338, P310, P321, P363, P403+P233, P405, P501 |

| NFPA 704 (fire diamond) | 3-2-2-W |

| Flash point | 6 °C (43 °F; 279 K) |

| Autoignition temperature | 490 °C |

| Explosive limits | Explosive limits: 2.8–25.5% (in air) |

| Lethal dose or concentration | LD50 oral rat 4300 mg/kg |

| LD50 (median dose) | LC50 rat inhalation 6.1 mg/L (4 h) |

| NIOSH | WX 3850000 |

| PEL (Permissible) | PEL (Permissible Exposure Limit) for Vinyltrichlorosilane: "1 ppm (5 mg/m3) as TWA |

| REL (Recommended) | REL (Recommended Exposure Limit) of Vinyltrichlorosilane is: "1 ppm (5 mg/m3) TWA |

| IDLH (Immediate danger) | 50 ppm |

| Related compounds | |

| Related compounds |

Trimethylsilyl chloride Methyltrichlorosilane Dimethyldichlorosilane Tetraethyl orthosilicate Vinyltrimethoxysilane |