Triethylsilane entered the chemical scene back in the 1940s, right around the post-war wave of industrial chemistry. Researchers in Europe, eager to expand organosilicon chemistry, started probing the potential of hydrosilanes. Triethylsilane took shape from those early experiments, showing up as a transparent liquid with properties quite unlike traditional reducing agents. For decades, synthetic chemists sought reliable and cleaner reagents, especially in the pharmaceutical and specialty chemical industries. Triethylsilane filled this gap, offering a solid alternative to tin-based reductants, which left toxic residues. Its development tied closely to the search for mild hydride transfer agents in the synthesis of complex organic molecules. Today, those early curiosities have sparked a global industry around engineered silanes.

Triethylsilane stands out as an organosilicon compound, drawing attention because it donates hydride so predictably in organic synthesis. Chemists know it as a versatile player, stable enough on the shelf but reactive enough where it counts. Its CAS Number is 617-86-7, and it often appears as a colorless liquid with a faint, pleasant odor. For anyone working in pharmaceutical labs or in silicone polymer manufacturing, this compound has become familiar, serving both as a reducing agent and, at times, as a precursor in the construction of new molecules. The ability to tailor reactions with such a compact reagent opens doors for creative molecule design.

Triethylsilane has the formula C6H16Si, and its molecular weight clocks in at 116.28 g/mol. With a boiling point of about 108–110°C and a melting point near −78°C, it behaves predictably under most reactor conditions. The compound dissolves in organic solvents such as hexane, ether, and benzene, lending itself easily to use in non-aqueous settings. Its density sits at 0.69 g/cm3—lower than water—which often comes in handy when separating reaction products. Flammability should not get overlooked, as both the liquid and its vapors catch fire with a simple spark. Its enthalpy and thermodynamic properties mean it acts as a mild, yet efficient, hydride donor—a trait prized among reduction chemists.

Manufacturers offer Triethylsilane in a range of purities, most often at 98% or higher for fine chemical work. Typical packaging uses amber glass bottles or metal containers to prevent UV degradation and minimize risk during transport. Labels always display hazard warnings, lot number, expiration date, and the chemical’s GHS pictograms. For shipping and storage, regulators across the United States and EU treat it as a flammable liquid, requiring strict adherence to fire safety procedures. Barcode tracking and digital inventory tagging have become common in recent years, helping labs monitor use and comply with regulatory standards.

Industry-scale production starts with trichlorosilane and ethylmagnesium bromide or lithium aluminum hydride. Chemists learned early that Grignard reagents react reliably with chlorosilanes, offering a route to trialkylsilanes with a good yield. By tweaking the stoichiometry and temperature during the addition, manufacturers can limit by-products such as diethylsilanes or tetraethylsilane. After completion, the mixture gets worked up via distillation in inert atmosphere to keep the product free of water and oxygen, both of which degrade it and introduce hazardous by-products. Advances in continuous-flow reactors have allowed producers to scale up output while lowering waste, helping environmental compliance efforts.

In organic synthesis, triethylsilane often shows up as the “go-to” mild hydride donor in the presence of suitable catalysts. For example, it participates in the reduction of carbocations, converting intermediates formed during acid-catalyzed reactions to their fully reduced forms. One common application is the cleavage of benzyl and allyl protecting groups, especially in the presence of strong acids or Lewis acids like trifluoroacetic acid or boron trifluoride. The compound steps up for reductive amination reactions, too—these transformations build carbon-nitrogen bonds with cleaner by-product profiles compared to alternatives. It also serves as a hydrosilylation agent in polymer chemistry. Modifications of triethylsilane itself remain rare, since the ethyl groups offer both bulk and stability, although researchers have explored functionalizing the silicon core for designer reagents in the lab.

Across catalogs and supply houses, triethylsilane carries a few synonyms. Some know it as triethylsilicon hydride, while older literature sometimes calls it TES. Major brands label it with clear product numbers, reflecting grade or regulatory status. Scientific articles may refer to it as Et3SiH, a shorthand notation instantly recognizable to practicing chemists.

Triethylsilane needs careful handling because of its flammability and ability to form explosive mixtures with air above its flash point. Labs enforce strict no-open-flame rules near the storage and use areas, and staff wear flame-resistant lab coats and splash goggles to guard against accidental spillage or fire. Storage happens in flammable safety cabinets, with temperature kept below 30°C. Emergency protocols call for immediate ventilation and spill containment using absorbent materials rated for organic solvents. Companies train workers to use both traditional incident management and new digital checklists for chemical hygiene. Material Safety Data Sheets detail not only first aid procedures but also disposal regulations, since waste streams containing triethylsilane often require special incineration.

Pharmaceutical chemists depend on triethylsilane as a gentle and selective reductant, especially in large-scale preparation of active pharmaceutical ingredients. Its mildness lets scientists build fragile, multi-step molecules without damaging valuable functional groups. In the world of materials science, it’s a key ingredient for specialty silicones—compounds that give adhesives, coatings, and electronic encapsulants their unique flexibility and durability. Analytical labs may turn to triethylsilane for sample treatment, where it plays a role in pharmaceutical impurity profiling. Outside these dominant application fields, research teams employ it for method development, process optimization, and pilot-scale runs to validate new drug synthesis pathways.

Active research around triethylsilane centers on developing more sustainable reduction methods and minimizing hazardous by-products in pharmaceutical production. Scientists are designing new catalytic systems—some based on earth-abundant metals—to improve selectivity while reducing reliance on rare or hazardous co-reagents. Automation technology is transforming both lab- and plant-scale use, allowing for on-demand dosing and precise reaction control. Some research groups have reported early success in recycling and recovery processes, using membrane or distillation technologies to reclaim unused reagent, driving down costs, and supporting environmental stewardship. Collaborative work between academia and industry is highlighting broader applications, such as creating advanced polymers and coatings for electronics.

Toxicity studies point out that triethylsilane poses moderate acute hazards to both humans and wildlife. Inhalation of vapors may cause headaches, dizziness, or respiratory discomfort, and skin contact often results in mild irritation. Long-term exposure data remain scarce, but the compound’s volatile nature puts an emphasis on engineering controls, such as fume hoods and closed transfer systems. Animal studies suggest low bioaccumulation potential, with metabolization leading to excretion as simple silanols and organic fragments. Environmental risk assessments urge caution, advising careful waste handling to prevent accidental release to soil or water. Regulatory bodies in Europe and North America issue clear guidelines on maximum airborne concentrations, and most industry players monitor exposure with real-time digital sensors.

Triethylsilane’s future looks linked to the drive for cleaner, safer, and more efficient chemical synthesis. Demand for low-toxicity pharmaceuticals and environmentally friendly polymers is growing. Universities and private labs keep testing new reaction conditions, catalysts, and recycling strategies to maximize the potential of this versatile reagent. Regulatory agencies are expected to tighten controls around flammability and emissions, pressuring manufacturers toward greener production routes. Global supply chains for organosilicon compounds stretch across multiple continents, bringing both challenges and opportunities for sustainable sourcing and cost control. As the push towards electrification and miniaturization continues in consumer electronics, materials chemists keep exploring triethylsilane-derived polymers for insulating coatings and flexible circuits. The compound’s adaptability and manageable risk profile put it on solid footing to remain a key tool for synthetic and materials chemists tackling the demands of the next decade.

Triethylsilane doesn’t come up much in everyday talk. Most people never see a bottle of it, but in chemical labs it shows up more often than you’d think. Picture a colorless liquid, vaguely reminiscent of ether in smell, packed in metal cans and bottles. This stuff helps scientists and manufacturers coax molecules into doing things they wouldn’t otherwise do. It won’t make headlines, but its uses shape plenty of products and discoveries behind the scenes.

At its core, Triethylsilane is a reducing agent. That means it’s useful for transferring hydrogen to other chemicals, which can change the structure of all sorts of molecules. This process gets called “hydrosilylation” in the world of chemistry. It allows chemists to build more complex compounds out of simple building blocks. In my own lab days, I watched colleagues breathe easier knowing Triethylsilane would help “clean up” stubborn chemical intermediates that other agents might leave rough or contaminated. No one cheered, but they all relied on its steady performance time after time.

Silicon-based chemicals like Triethylsilane have become a backbone for big industries, including electronics and pharmaceuticals. Even if you never touch the stuff, you probably own a piece of electronics or take medicine that owes some step of its journey to Triethylsilane. Its hydrogen-donating power works gently compared to more aggressive reagents, so fragile or sensitive package molecules survive the process. In a world that keeps asking for more complex and precise therapies, that kind of tool makes a big difference.

Pharmaceutical synthesis leans hard on Triethylsilane. The hunt for new drugs isn’t easy. Chemists fine-tune small molecules by adding or removing tiny chemical features, and small mistakes sink whole batches. Triethylsilane helps them swap out chlorine atoms for hydrogens or reduce nitro groups to amines smoothly, saving on waste. A better yield in these reactions makes medicines cheaper and faster to produce, which means doctors can offer treatments to more people sooner.

Specialty polymers also benefit. Triethylsilane plays a role in making siloxanes, which end up in adhesives, coatings, and sealants. Better adhesives hold delicate microchips in place. Improved coatings protect cars and gadgets against scratches and weather. The stuff behind these advances rarely wins glamour awards, but it makes a real difference in the finished product’s reliability.

Tinkering with chemicals like Triethylsilane demands respect—this isn’t something to splash around carelessly. It can ignite under the right conditions, and it doesn’t mix well with water. My own nervousness working around it wasn’t misplaced, given its flammable vapor and capacity to form explosive mixtures with air. Nothing focuses the mind like handling a substance that can turn a routine synthesis into a five-alarm fire if you forget your protocols. Responsible labs keep safety gear close, use fume hoods, and never work alone. Public agencies expect clear safety procedures for anyone storing or shipping this material.

Safer alternatives keep popping up, but few match Triethylsilane’s blend of efficiency and selectivity in tough synthetic jobs. Moving forward, the field needs ongoing research into greener, safer reducing agents that can fill the same niche. Researchers continue trying new compounds and new protocols, making sure that one day, labs and manufacturers can craft complex molecules with even fewer risks. Until then, Triethylsilane remains a tool people count on, as long as respect for its hazards goes hand in hand with its technical gifts.

Triethylsilane carries the formula C6H16Si. This formula looks simple, but it marks the difference between theory and practice in a chemical lab. Six carbons, sixteen hydrogens, and silicon—as soon as you spot this, you know you’re dealing with one of those organosilicon compounds that serve a real-world purpose. It stands apart from more familiar silanes like tetraethylsilane, which often crowd introductory charts but offer completely different properties and uses.

My first exposure to triethylsilane came during a college organic synthesis project. Its power as a reducing agent didn’t show up in flashy explosions or vibrant color changes. It worked quietly to convert challenging intermediates into useful products, and the reaction was far more straightforward than other reduction steps crammed into my lab notebook. Chemists find value in this molecule because it donates hydrogen atoms in ways that feel precise. You want to reduce a carbonyl or cleave a protective group? This silane often rises to the occasion.

The material finds its way into pharmaceutical development. Reductions using triethylsilane often help in building valuable fragments for new drugs, especially those with sensitive functional groups that fall apart under harsher conditions. Its reputation as a gentle, reliable source of hydride ions puts it ahead of more aggressive alternatives, so sensitive molecules don’t break down or rearrange into byproducts. Companies working on specialty polymers and coatings also look to triethylsilane, chasing bond-forming reactions that won’t tolerate water, strong acids, or high heat.

Every chemist handling triethylsilane needs to remember: safety isn’t just about gloves and goggles. Volatile silanes may ignite in air and release flammable gases, even from small spills. I’ve seen lab benches scorched because someone underestimated vapors or left a waste bottle slightly open. You have to handle it in a fume hood, cap containers tightly, and keep sources of static electricity far away. There’s a slow learning curve as you try to avoid overconfidence; small mistakes can multiply fast. Monitoring local regulations about storage and disposal helps avoid harmful exposure or dangerous buildup of gases in shared facilities.

Reliable lab handbooks and chemical safety databases rate triethylsilane as a flammable liquid, noting its boiling point around 107°C and its capacity to form explosive mixtures with air. Historically, the National Institutes of Health and other agencies publish clear hazard summaries. Experienced researchers cite case studies where improper use contributed to fires or interrupted research. The American Chemical Society and professional safety courses repeat the same message—never take shortcuts with these liquids, because real people have been hurt in the process.

Careful chemical handling pays off in health and productivity. You reduce waste, avoid downtime from accidents, and return home without incident. It’s impossible to exaggerate the impact of treating reagents like triethylsilane as both a privilege and a responsibility. Good habits, clear documentation, and respect for known hazards help prevent the next accident and keep scientific progress on track.

As chemists hunt for cleaner, safer, and more efficient reactions, triethylsilane sometimes steps to the side for newer hydride donors or green chemistry tools. Still, its reputation stands. Memory sticks with you after you’ve run a safe, successful reduction using this formula: C6H16Si. Understanding the chemistry lets you put these molecules to work, solve pressing problems, and shape the future of science with care.

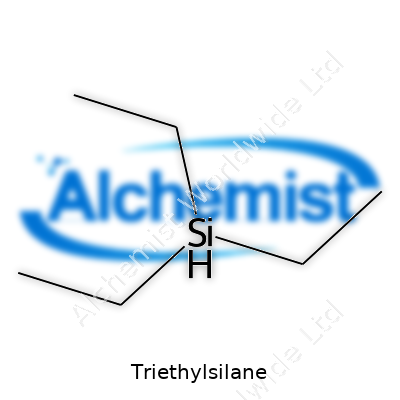

Triethylsilane pops up in research and chemical labs, mainly for its use as a reducing agent. On the molecular side, it's got three ethyl groups attached to a silicon atom with a single hydrogen atom hanging off the silicon. The formula sounds simple, but things get interesting once this clear liquid hits a workbench.

Most folks will never run into triethylsilane unless they work with specialty chemicals. In the lab, its hazards deserve real attention. This stuff gives off flammable vapors, and if a researcher gets careless with open flames or ignition sources, it can light up in no time. The flash point sits at 27°C—lower than a summer afternoon in a lot of places—which means even room temperature storage involves risk.

Breathing in the vapors can irritate the nose and throat, causing coughing or even dizziness if the air isn’t moving enough. There’s no well-documented chronic toxicity in people because exposure in daily life is pretty much nonexistent. A few animal studies hint at mild irritation and little else, but they don’t give the full picture for long-term or high-dose exposure. I’ve seen chemists brush off the threat because the liquid seems mild compared to strong acids or bases. That overconfidence quickly fades after accidental splashes or finding out what a poorly ventilated lab can feel like.

Spills pose a double whammy: not only can fire break out, the liquid and its vapors can irritate skin and eyes. Glove protocol and safety goggles are a must. Some technicians, including me during my graduate years, get a little lax after dozens of uneventful uses. The lesson usually clicks only after experiencing a burning sensation on your skin or a fuss with the fire alarm. It takes just a splash or whiff at the wrong moment for a quick reminder that standard PPE isn't just a box to check.

Triethylsilane doesn’t stick around in soil or water for long and breaks down over time, but that doesn’t mean it’s harmless outdoors. Spills into drains or water systems can harm aquatic life. Waste should go into proper chemical waste streams. I’ve watched many labs get dinged in safety audits for improper solvent disposal, which sometimes traces back to “not-so-dangerous” chemicals like this one.

Frequent training and visible safety reminders help a lot. Chemical safety doesn’t need to sound sinister to be effective—good communication and honest stories about past incidents do more than a stack of rules. I always urge newcomers to review the SDS in detail and respect every material with the same care as the nastiest stuff on the shelf. Routine reviews of storage protocols—keeping quantities small, using flame-proof cabinets, and labeling everything—can prevent most accidents. Good ventilation and fire extinguishers that handle chemical fires remain as essential as ever.

Triethylsilane doesn’t scare most chemists, but it commands respect. Don’t leave safety up to luck; close calls with flammable liquids happen too quickly to wish for a do-over. Better awareness and solid routines keep labs productive and people healthy.

Occupational Safety Data – PubChem, National Institutes of Health

GHS Classification – European Chemicals Agency (ECHA)

Laboratory Safety Practices – American Chemical Society Guidelines

Triethylsilane plays a key role in organic synthesis, especially as a reducing agent in labs and industrial settings. This colorless liquid doesn’t make headlines like some chemicals, but anyone who’s transfered or stored it knows it’s not a free-for-all. Getting this bit wrong creates safety risks nobody wants in a workspace.

I once watched a colleague grab a loosely capped bottle off a bench. A sharp supervisor spotted the mistake, reminding everyone that triethylsilane can react with water and air. Exposure invites decomposition, possibly releasing silane gas—which can spark when it hits oxygen. Storing it in airtight containers turned into our lab’s unwritten rule, and nobody pushed their luck after that.

Direct sunlight and high temperatures just don’t mix well with triethylsilane. Even though it’s a stable liquid under the right conditions, you can’t store it in a sunny window or near radiators. Safety data sheets recommend keeping it in a cool spot, typically below 25°C (77°F). It's not just red tape—one inattentive summer day, we found residual fumes collecting in a poorly ventilated storage cabinet under a skylight. After that, everyone picked shaded shelving, away from any potential heat sources.

Poor material choices lead to leaks or spills. Not every bottle works. Triethylsilane dissolves some plastics, so glass works best for long-term storage. If plastic finds use, HDPE or Teflon stand out, but regular lab-grade containers sometimes fail. I learned this the hard way after a cracked bottle left a mess I’ll never forget. Now I always check compatibility charts before trusting any container.

Triethylsilane catches fire easily. Fume hoods and explosion-proof refrigerators helped my old lab stay incident-free. Open flames or spark sources near a shelf holding these bottles always drew a quick correction from supervisors. Grounded metal shelves, a working fire extinguisher, and a clear escape route—these basics got hammered home each year on safety refresher day.

One of the smartest moves in our routine involved meticulous labeling. Each bottle not only named the chemical, but also showed the purchase and open date. Inventory sheets—both digital and physical—prevented unexpected shortages and stopped old or degraded triethylsilane from hanging around. I remember a close call when an unmarked container almost sneaked into a reaction setup. From then on, nobody let labeling slide, ever.

Book learning matters far less than hands-on training. Newcomers got paired with veterans for their first few months. Accidents stayed rare because discussions about storage and handling happened all the time, not just at orientation. That ongoing mentorship built a learning culture, not just a checklist approach, and reduced both mistakes and near-misses over the years.

Decent storage boils down to airtight, clearly labeled glass bottles, kept cool and away from light, heat, and open flames. Good training, constant vigilance, and plain old peer pressure stop trouble before it starts. All these steps stem from a mix of real-world mishaps and a commitment to better habits. Safety doesn’t just appear from guidelines; it takes focus, care, and people who look out for each other every step of the way.

Triethylsilane lands on many chemists’ benches for a reason. Over time, I’ve seen it save stalled projects and help streamline tricky steps in synthesis. Some reactions just need a gentle push, and Triethylsilane often provides exactly that. There’s a reputation for being the mild hydride donor that offers more control than the classic heavy hitters like lithium aluminum hydride.

Old-school hydride reagents bring a punch, but they don’t always respect sensitive features in molecules. Triethylsilane gives chemists an option to dial down that reactivity. For example, if you want to reduce certain protecting groups or functional groups in a crowded molecule, it’s frustrating to see your target fall apart under the force of sodium borohydride. Triethylsilane often comes through, especially when paired up with a Lewis or Brønsted acid. Carbocation intermediates aren’t afraid of Triethylsilane. They readily capture its hydride, leading to cleaner products with fewer side reactions. In pharmaceuticals, that gets important real fast, especially if a mischievous byproduct slows down development or ruins purity.

At the end of a complex synthesis, you don’t want a harsh deprotection step to ruin months of work. Silyl ethers and other robust protecting groups need something gentle but effective. Triethylsilane, under the guidance of acid, gives a hand here. It snips away benzyl or benzylic-based protecting groups without rattling ester or amide bonds elsewhere. This lets folks keep sensitive bits intact while finishing off a molecule with confidence. Experienced hands reach for Triethylsilane in these situations—its record speaks for itself.

Selectivity can make or break a project. With Triethylsilane, chemists pick up an edge—especially in generating and quenching reactive intermediates like carbocations or in radical chemistry. With the right catalyst, you can fine-tune what gets reduced and what stays put. In some syntheses, particularly in the natural product field, life gets easier if you can coax a selective hydride transfer using milder reagents. Triethylsilane often steps in as that precise tool, where adding any more force would punch holes elsewhere in a carefully crafted molecule.

Bringing a molecule from the lab bench to a production plant isn’t simple. Solvent and reagent choices get extra scrutiny. Many scale-up teams favor Triethylsilane for its fluid handling, low volatility compared to smaller silanes, and safer profile compared to more reactive hydrides. I’ve seen process scientists lean on this compound during kilo-lab campaigns, valuing the consistency and reduction in hazardous byproducts. In regulated settings, any drop in waste or hazard counts as a win.

Triethylsilane isn’t the cheapest item on the shelf, but teams often justify the expense with better yields and fewer purification headaches. Less waste and rework mean faster progress. For research teams under budget scrutiny, reducing the need for multiple purifications carries a lot of weight. On the sustainability side, chemists keep searching for ways to recycle silanes or replace them with greener options. But right now, Triethylsilane strikes a practical balance between reactivity, safety, and effectiveness where few alternatives truly match its performance.

As chemistry leans toward greener, safer reactions, the whole field benefits from finding reagents that keep complexity in check. Triethylsilane fills an important role by staying mild but effective. Academics and industry researchers both have an interest in finding recycling schemes or catalytic paths that use silane more efficiently. Until then, many projects that demand delicate handling of complex molecules will continue to depend on Triethylsilane as a uniquely suited solution.

| Names | |

| Preferred IUPAC name | triethylsilane |

| Other names |

Triethylsilicon hydride Triethylsilicane |

| Pronunciation | /traɪˌɛθ.ɪlˈsaɪ.leɪn/ |

| Identifiers | |

| CAS Number | 998-30-1 |

| Beilstein Reference | 1696806 |

| ChEBI | CHEBI:33398 |

| ChEMBL | CHEMBL156342 |

| ChemSpider | 54633 |

| DrugBank | DB14629 |

| ECHA InfoCard | ECHA InfoCard 100.003.859 |

| EC Number | 203-905-0 |

| Gmelin Reference | 11203 |

| KEGG | C14297 |

| MeSH | D017837 |

| PubChem CID | 12061 |

| RTECS number | VV4600000 |

| UNII | 4C6R2XMS8V |

| UN number | UN1993 |

| Properties | |

| Chemical formula | C6H16Si |

| Molar mass | 162.38 g/mol |

| Appearance | Colorless liquid |

| Density | 0.726 g/mL at 25 °C |

| Solubility in water | Insoluble |

| log P | 1.98 |

| Vapor pressure | 4.3 mmHg (20 °C) |

| Acidity (pKa) | 31.0 |

| Basicity (pKb) | Triethylsilane does not have a reported pKb value. |

| Magnetic susceptibility (χ) | −22.0×10⁻⁶ cm³/mol |

| Refractive index (nD) | 1.382 |

| Viscosity | 3.97 cP (20 °C) |

| Dipole moment | 0.09 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 358.7 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -241.1 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -2030 kJ·mol⁻¹ |

| Hazards | |

| GHS labelling | GHS02, GHS07 |

| Pictograms | GHS02,GHS07 |

| Signal word | Warning |

| Hazard statements | H225, H319, H336 |

| Precautionary statements | P210, P261, P280, P301+P310, P304+P340, P305+P351+P338, P312, P330, P501 |

| NFPA 704 (fire diamond) | 1-4-2-W |

| Flash point | 23 °C |

| Autoignition temperature | 215 °C |

| Explosive limits | Explosive limits: 1.1–8.4% (in air) |

| Lethal dose or concentration | LD50 (oral, rat): >2000 mg/kg |

| LD50 (median dose) | LD50 (median dose): Oral, rat: 7480 mg/kg |

| NIOSH | TTW12750 |

| PEL (Permissible) | Not established |

| REL (Recommended) | 10 ppm |

| IDLH (Immediate danger) | No IDLH established. |

| Related compounds | |

| Related compounds |

Trimethylsilane Triphenylsilane Triethylgermane Triethylstannane |