Trimethylchlorosilane, commonly known as TMCS, kicked off its story back in the mid-twentieth century as silicon-based chemistry began offering new tools for both industry and science. Folks in chemical manufacturing realized that chlorosilanes opened the door to silicone polymers, whose uses stretch from waterproof coatings to flexible medical devices. TMCS in particular gave chemists a straightforward way to tweak surfaces and stabilize silanol groups, letting researchers produce siloxane chains with a steady hand. Over the years, demand for faster electronics, sleeker sealants, and tougher coatings has just kept this molecule in the spotlight. Explorers in organic synthesis and materials science still look to TMCS when piecing together new compounds and surface treatments.

TMCS appears as a colorless, fuming liquid with a distinct, pungent odor. Companies produce and ship it in drums and canisters lined with materials that hold up against its reactivity. From labs to large-scale production, chemists grab for TMCS to introduce trimethylsilyl protecting groups, to cap silica surfaces, and to render glassware or polymer films hydrophobic. It enters products like adhesives, sealants, and even personal care items, where modified silanes keep gels stable and water off. In day-to-day practice, anyone working with this chemical pays extra attention to labeling, handling instructions, and storage guidelines, given its punchy reactivity with moisture.

Trimethylchlorosilane shows a boiling range around 57–58°C and boasts a density that clocks in near 0.857 g/mL at 20°C. In air, it fumes quickly, releasing hydrogen chloride when it touches water vapor. Its vapor can catch fire if concentrations and temperatures tip past certain thresholds. Chemists value TMCS for its aggressive silylating action. With its Si-Cl bond, it doesn’t linger unreacted for long when moisture or nucleophilic reagents appear. Handling this liquid without proper protection easily leads to skin burns and persistent vapor irritation. Storage usually ends up in steel drums kept away from heat, tightly sealed to prevent hydrolysis.

Chemical suppliers often report a purity exceeding 99%, with fresh drums sometimes surpassing that mark. Labels carry UN number 1298, marking it as a flammable liquid and corrosive. Safety Data Sheets put TMCS squarely in hazard class 3 and 8. Lab containers bear stopcocks and gaskets made from materials that don’t crumble when chlorosilanes pass through. To trace reliability, reputable producers add batch numbers and reference gas chromatography results. Users check for water content, since even tiny traces knock down yields and cause storage headaches. Each batch log tracks production, purification, and shipment to keep up with quality and regulatory rules around the globe.

Industry typically prepares TMCS by passing methyl chloride over silicon at high temperatures to get methylchlorosilanes, then separating out the trimethyl variety by fractional distillation. The reaction might start with silicon powder and pure methyl chloride gas, both fed into a fluid-bed reactor running upwards of 250°C. From this soup of methyl-substituted silanes, skilled operators distill off the desired fraction using precision columns. A string of scrubbing and drying steps follows to pull out leftover water, HCl, and unwanted silicon compounds. Waste streams need careful treatment, since HCl gas and chlorinated silanes make for serious environmental headaches if ignored.

TMCS earns its keep in organic synthesis by introducing trimethylsilyl groups onto alcohols, acids, and amines, giving chemists a handle on reactivity and purification. For example, mixing TMCS with a mild base like pyridine lets a carboxylic acid’s active hydrogen pop off, replaced by a trimethylsilyl group. In silica surface modification, TMCS reacts with silanol groups, “capping” the surface and blocking further water attraction. Modified glassware laughs off moisture and sticky organics. Folks in gas chromatography use silylation with TMCS to ready polar compounds for analysis, since it transforms sticky analytes into volatile silyl ethers that zip through columns. Over the years, researchers have even looked to TMCS to tweak properties of nanoparticles, engineer new hydrophobic surfaces, and prep polymer films for adhesion.

Trimethylchlorosilane goes by lots of names, including chlorotrimethylsilane and TMSCl. Some call it TMCS or simply “silicon chloride, trimethyl.” Trade names depend on the producer: vendors like Sigma-Aldrich, Alfa Aesar, and Gelest all have catalog numbers specific to their own lines. Chemists keep watch for synonyms to dodge confusion, since some regional suppliers stick with older IUPAC or manufacturer codes. If you spot bottles with names like methylchlorodimethylsilane or trimethylsilyl chloride, you’re usually in the right ballpark—though a double-check of molecular structure always helps.

Trimethylchlorosilane demands respect from anyone opening a bottle. As a strong irritant and water-reactive liquid, TMCS can blister skin, scorch lungs, and trigger fires if spills go ignored. Lab protocols require chemical-resistant gloves, full goggles, and splash-proof coats. Fume hoods work overtime when TMCS enters the picture, keeping vapor out of breathing zones and preventing the spread of HCl gas. Storage sits far from water, acids, or bases, with emergency spill kits ready. Teams review handling instructions and first aid before unscrewing caps. Waste disposal routes it through specialist destruction or neutralization, since sewer or open burning leads straight to regulatory violations and workplace injuries.

Trimethylchlorosilane works quietly across diverse industries. In pharmaceuticals, it protects reactive groups and preps molecules for downstream reactions. Researchers in chromatography depend on TMCS to prepare samples, making complex mixtures easier to analyze. The manufacturing of silicone rubbers, foams, and coatings draws on TMCS as a chain-stopping additive and to reduce unwanted reactivity. Dental adhesives, consumer sealants, and anti-fog coatings owe their durability and moisture resistance to clever use of chlorosilanes like TMCS. Even electronics fabrication leans on TMCS when modifying wafer surfaces, increasing yield and preventing defects in microchips. In my own research days, sample derivatization with TMCS proved crucial to turn sticky plant resins into crisp, traceable peaks on a gas chromatograph, making troubleshooting a chemical puzzle just a little easier to solve.

Universities and industry laboratories still experiment with TMCS, searching for greener preparation routes, novel surface treatments, and upgrades in polymer chemistry. Efforts focus on reducing waste—cutting out excess methyl chloride and silicon powder, for example—while squeezing every last gram from expensive feedstocks. Some teams tweak the surfactant properties of TMCS-modified surfaces, chasing better biomedical coatings that fight infection or speed healing. Analytical chemists write up protocols optimizing TMCS-based sample prep, aiming for faster derivatization with lower reagent use and cleaner results. On the materials side, researchers design hydrophobic nanoparticle coatings and shape memory polymers with silyl chemistry front and center.

Toxicology studies single out TMCS as an inhalation and contact hazard. Acute exposure leads to mucosal irritation, coughing, chemical burns, and sometimes severe eye injury. Rats in controlled studies showed respiratory distress after high exposures. Breakdown to trimethylsilanol and hydrochloric acid in tissue hints at the main threat—acidic burns and disruption of cellular membranes. Repeated handling with insufficient protection leaves workers with dermatitis and respiratory symptoms. Environmental fate studies indicate TMCS hydrolyzes quickly in moist soil and water, forming silanols and salt. Regulatory bodies classify it under hazardous chemical lists, demanding strict workplace monitoring and emergency response planning. Practical experience in busy synthesis labs proves these measures protect workers far better than shortcuts or outdated advice.

As industries lean into more sustainable practices, TMCS will face pressure to shed hazardous byproducts and shrink its carbon footprint. Process engineers look for continuous-flow reactors that cut energy use and improve yield, chipping away at feedstock inefficiency. Advances in protective automation—think robotics and sealed reagent delivery—keep people further from harm. In coatings and polymer research, chemists aim to swap out traditional organochlorosilanes for safer alternatives that reduce HCl emission without losing effectiveness. Environmental policy and green chemistry standards nudge manufacturers to find substitutes or remodel the supply chain. But for surface modification and selective silylation, TMCS still offers speed, reliability, and versatility that few reagents match. I expect to see smarter recycling, digital monitoring, and greener derivatives—while the backbone chemistry remains a go-to tool for building the next generation of materials, pharmaceuticals, and clean technologies.

Trimethylchlorosilane often shows up in a chemist’s toolbox but its trail stretches far beyond the lab bench. This clear, fume-producing liquid has a knack for reacting with water and alcohol, which sparks countless uses in industries from electronics to construction. Most people never hear about it, and yet it shapes plenty of what we see and touch.

A big use for trimethylchlorosilane lies in making things water-repellent. On glass, ceramics, or electronic components, manufacturers treat surfaces with this chemical to help them resist fog, dust, or moisture. Think about the inside of a test tube or the face of a modern solar panel. These items need a protective layer so grime doesn’t build up or water doesn’t cause damage. A quick dip or wipe with trimethylchlorosilane and suddenly these surfaces stay clearer and last longer.

In my own experience as a general science teacher, I saw first-hand how stubbornly things can stick—especially when you don’t want them to. Trimethylchlorosilane solves this problem. Industrial workers use it to stop adhesives or paint from clinging to things like molds in manufacturing. The process involves treating the mold with the chemical so the end product slips right out without leaving behind a mess, which reduces waste and saves time. Silicone rubber production relies on this step to churn out everything from bakeware to medical implants.

Computer chips demand precision at the tiniest level. During the manufacturing of semiconductors, technicians call on trimethylchlorosilane to protect parts of a circuit or prepare the wafer’s surface. Without this chemical, contamination from dust or stray moisture would mess up the tiny wires and transistors, leading to slower computers or phones. Cutting corners could cost entire production lots.

Drug research teams lean on trimethylchlorosilane to build certain molecules. It works as a blocking agent during organic synthesis, which means it helps keep one end of a molecule from reacting while the other end hooks up in just the right way. This option allows chemists to steer the reaction path clearly, boosting both safety and yield. Companies save research money and get more reliable medicine out the door.

Safety always calls for attention with this chemical. It chokes up the lungs if you breathe in those stiff fumes, and it burns the skin in seconds. Factories and labs need strong ventilation and well-trained handlers. Over in the environment, trimethylchlorosilane breaks down when mixed with water but produces hydrochloric acid, which can kill fish or corrode drains. Careful handling and disposal matter not just for workers but for neighborhoods downwind and downstream. U.S. Occupational Safety and Health Administration (OSHA) limits exposure and classifies this as a hazardous material, stressing the need for gloves, eye protection, and fume hoods.

Moving forward, plant managers and safety officers train staff to respect the danger. Good storage and spill-control kits show up in every facility that stores chemicals. Some manufacturers now look for safer alternatives, especially for less technical tasks, but substitutes haven’t matched the reliability or performance in every role yet.

Plant tours reveal just how much a single clear liquid transforms industries and keeps expensive equipment running, coatings smooth, and surfaces shining. Trimethylchlorosilane doesn’t grab headlines, but most people benefit from its handy chemistry every day.

Trimethylchlorosilane has a reputation in the lab for being both useful and tricky. If you’ve spent any time in chemistry, you know harsh chemicals aren't just a footnote in a textbook; they make life difficult if you don’t respect them. This compound can throw off strong fumes and will react in your face if you drop a splash of water nearby. I learned real respect for this stuff during grad school—after witnessing a close call when a colleague underestimated how much vapor comes off even a tiny spill.

Trimethylchlorosilane brings two main problems to the bench. First, it reacts sharply with water, shooting out hydrochloric acid gas. You breathe that in and your lungs won’t let you forget it. Skin exposure leads to painful burns. It’s also volatile, so evaporation and fumes stay a real threat. NIOSH and OSHA flag this compound as acutely toxic. Anyone walking into a lab with this chemical in play faces eye, respiratory, and skin hazards. Cases of chemical burns, severe irritation, and lasting health issues have come up—sometimes just from underestimating how far those vapors can wander.

Treating Trimethylchlorosilane with respect means never handling it without proper gear. Skip the wool lab coat—get something chemical-resistant, preferably neoprene or nitrile. Gloves matter, and not the cheap ones; thick, tested nitrile gloves that you can swap frequently stand up to splash risk. Splash goggles and a full-face shield protect against stray droplets or sudden splatter—which happens more often than newcomers expect. Don’t forget chemical fume hoods. Even a sealed bottle can send out invisible vapors, so no handling on open benches or by the sink.

Moving this chemical gets dicey if you don’t pay attention. Keep everything tightly sealed. Use secondary containers—rigid plastic ones—to avoid a mess if the main vessel breaks. Keep bottles in well-ventilated, cool, dry cabinets. Moisture doesn’t just degrade the chemical, it creates a dangerous reaction. Never walk away from an open bottle; someone distracted by a phone or conversation could walk into trouble quickly. It’s easy to forget until you see someone learn it the hard way.

Spills start as simple mistakes—sometimes a shaky hand, sometimes a rushed transfer. Spills of this chemical call for trained hands and the right absorbents. Standard paper towels only spread it around and make gas clouds worsen. Vermiculite and neutralizing agents should stay within reach in designated areas. Always label waste clearly, using containers that won’t react with acidic or reactive residues.

It helps to run regular training, not just one-off lectures. I learned plenty from informal sessions where seasoned lab staff shared stories—real mishaps, near misses, and fixes that worked. Folk wisdom saves more skin than any checklist. Relying on a checklist without context leaves room for error. Labs and workshops that emphasize communication, up-to-date safety data, and ongoing discussion build safe routines faster than any poster on the wall.

It’s easy to say, “follow the rules,” but Trimethylchlorosilane reminds us every chemical creates new situations. Investing in the right equipment, updating procedures based on real incidents, and asking questions about the last time people ran a drill makes a difference. Chemists owe each other their safety—not just through gear, but by paying attention and learning from each other. Every small attention to detail on the bench adds up to a safer workplace for everyone.

Trimethylchlorosilane shows up a lot in labs and industrial settings, partly because it lends itself well to surface treatments, making chemical bonds that last. Most chemists pay a lot of attention to its storage for a simple reason: it reacts fast with moisture. Open a bottle and you might catch the acidic vapor, a sharp smell in the air—proof enough that it does not mix quietly with water.

Water and trimethylchlorosilane cannot share space. In the presence of even small humidity, this liquid sheds hydrochloric acid gas and forms trimethylsilanol. That gas stings eyes and noses and eats at metal. A friend who left a loose cap on a bottle found his whole shelf sticky and corroded only a week later. Glassware feels the pain too, with etching and clouding. Keeping it bone-dry is more than a best practice.

Metal drums seem sturdy, but many corrode from acid fumes. Polyethylene and polypropylene win points, refusing to break down in contact with the chemical. Thick-walled amber glass bottles might get the job done, but only if the cap seals absolutely tight and nobody forgets it open. My former workplace insisted on septum-capped vials for smaller amounts, letting us pull what we needed with a dry syringe—never a drop spilled or fume released if done right.

A cool, dry storage room keeps trouble away. The temperature should not climb much above room temperature, as pressure builds inside containers and risks leaky seals. Humidity is always a risk; so choose a desiccator or put a tub of desiccant in the cabinet. The best setups involve ventilated storage—ideally a fume hood or a special flammable cabinet with vent connections. Building codes and OSHA rules stress this because one whiff can turn a laboratory accident into a medical emergency.

I always learned to separate trimethylchlorosilane from strong bases, oxidizers, and—most critical—water sources. You cannot put it under the same hood as open beakers of water or store next to safety showers. Clear, bold labeling pays off: if someone reaches for the wrong bottle while wearing damp gloves, things go sideways fast. Double-checking dates and seals saves money and hassle, since old stock tends to degrade or build up enough pressure to pop a cap.

Not enough gets said about the personal risk in mishandling volatile reagents. Goggles, gloves, and lab coats aren’t just OSHA theater—they protect against splashes and invisible fumes. Spill kits should sit near the chemical locker, and everyone using the storage should get refreshers on emergency procedures. Investing in safer storage means fewer health scares and avoids EPA citations that nobody wants.

Labs and warehouses benefit from routine safety walks. A checklist used monthly helped my last team catch small leaks and expired bottles before they spelled trouble. Asking for feedback from staff using the chemical every week led to a few good changes, including moving supply storage near ventilation rather than under a crowded bench. If the work stays people-focused, storage stays safer.

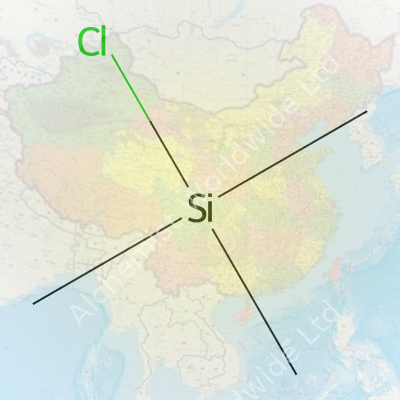

Trimethylchlorosilane, with the formula C3H9ClSi, brings together three methyl groups, a chlorine atom, and a silicon atom. At first glance, it might sound like just another compound from a list, but a closer look reveals its reach across numerous industries. I still remember, from my first year in an industrial lab, spotting this colorless liquid next to the glassware—handled carefully, respected for both its reactivity and its utility.

Few compounds are as transformative as trimethylchlorosilane in a chemist’s toolkit. The silicon-chlorine bond in this molecule reacts quickly with water, alcohols, and even surfaces. That makes it especially useful for adding a “trimethylsilyl” group to compounds or to glassware. In chromatography, silanization involves this compound: it coats surfaces, shutting down pesky sites that could skew the results. The silicon center acts like a clever anchor, holding on tight to different organic fragments.

The bigger story here, though, comes from how it works in labs and plants. This formula paved the way for safer and more durable optical fibers, and it improved yields in pharmaceuticals. People often overlook the hard science behind the ease of analysis in modern labs, but I’ve seen firsthand how clogged columns or inconsistent results used to waste hours of researchers’ time before silylation with trimethylchlorosilane became standard practice. The efficiency boost translates directly to savings and safer products for the public.

Handling trimethylchlorosilane takes strict discipline. Contact with moisture creates hydrochloric acid vapor, which can wreak havoc on lungs and mucous membranes. I still recall a coughing fit in a crowded teaching lab, triggered when someone missed a spill. You learn quickly that chemical formulas don’t tell the whole story—proper fume hoods and PPE can make all the difference. Reports show that extended exposure to the vapors damages respiratory health.

Disposal brings its own challenges. Dumping excess or stormwater-contaminated waste can lead to silicon-based residues that persist in soil and water. Regulatory bodies stepped in not out of bureaucratic whim, but because of evidence linking trace chemicals to broader environmental changes. C3H9ClSi isn’t just another reagent—it has real-world impacts outside the lab.

Careful training matters more than any printed warning label. Young chemists need hands-on learning about its hazards and proper waste management. Some manufacturers are innovating with less volatile alternatives or built-in closed handling systems. Even small steps, like improved waste capture and routine leak checks, cut down on contamination and workplace incidents.

Consumer products benefit when raw materials get scrutinized at each step. That means everyone from suppliers to end users has a stake in making the best choices for health and the environment. Chemistry’s building blocks hold promise and risk—C3H9ClSi stands as a reminder of both the power and the responsibility that come from working at the molecular level.

Trimethylchlorosilane shows up on chemical labels in labs, factories, and occasionally in headlines about chemical spills. The name alone stirs up questions. This clear, colorless liquid gives off fumes with a sharp, distinct odor. Its primary job is in the manufacturing of silicone-based products, coatings, pharmaceuticals, and even chip fabrication. No one walking into a hardware store is likely to run into it, yet people downstream from factories or disposal sites still have questions about safety.

Getting trimethylchlorosilane on your skin or breathing its vapor brings more than temporary discomfort. The chemical reacts briskly with water, including the moisture that lines your nose, throat, and lungs. Contact can cause coughing, chest pain, and lung irritation. Prolonged exposure ramps up the risks significantly—scarring or chemical burns in the airway can follow, along with long-term respiratory trouble. Short-term eye or skin contact leads to redness, pain, and serious burns. These accounts come from industrial accident reports—nobody is guessing.

OSHA and NIOSH list it as a hazardous substance and urge strict workplace controls: fume hoods, chemical splash goggles, and gloves rated for chemical resistance. I’ve seen workers get lazy with chemical protocols, only to sit through an emergency eyewash session. This stuff doesn’t forgive mistakes.

People sometimes assume that if a liquid is clear, it’s harmless once it washes down the drain or evaporates. Trimethylchlorosilane brings a twist. It reacts with water almost immediately, turning into hydrochloric acid and trimethylsilanol. Acid formation isn’t good news for rivers, streams, or water treatment plants. Hydrochloric acid lowers pH and stresses aquatic life. Trimethylsilanol, by itself, has low toxicity, but persistent environmental release still creates unplanned chemical cocktails in waterways.

Improper drum rinsing, leaky valves, or unmonitored storage lead to headaches for emergency crews. Any spill in a rainstorm risks a chemical chain reaction. I once helped with a municipal training module for hazardous material containment; fire chiefs flagged trimethylchlorosilane as a “high priority” drill, especially near population centers.

Industry guidance and regulation help, but enforcement at every storage site, truck route, and waste bin brings real challenges. Fines and warning signs don’t keep workers safe if training slides glitter by on autopilot. Safer chemical alternatives exist for some uses, but the market keeps trimethylchlorosilane in play because it works fast and reliably.

Best practice means installing leak detection, requiring written safety plans, and running drills that treat spills as inevitable, not rare. Sharing “close call” stories at safety meetings does more to shape behavior than a thousand-page manual. Investing in processed chemical containment technology, like double-seal tanks and automatic shut-off valves, proves its worth through avoided lawsuits and hospital visits.

At a community level, more public disclosure about chemical inventories helps neighbors make emergency plans too. While trimethylchlorosilane isn’t crawling into every home, it warrants attention, respect, and tight handling wherever it travels.

| Names | |

| Preferred IUPAC name | Chloro(trimethyl)silane |

| Other names |

Chlorotrimethylsilane Trimethylsilyl chloride TMCS Silane, chlorotrimethyl- Trimethylmonochlorosilane |

| Pronunciation | /traɪˌmɛθ.ɪl.klɔːrəˈsɪ.leɪn/ |

| Identifiers | |

| CAS Number | 75-77-4 |

| Beilstein Reference | 1208734 |

| ChEBI | CHEBI:85073 |

| ChEMBL | CHEMBL15461 |

| ChemSpider | 8602 |

| DrugBank | DB11273 |

| ECHA InfoCard | 14c9a0a7-5a2a-4e6d-8f97-85a6e1dab678 |

| EC Number | 200-967-3 |

| Gmelin Reference | 82268 |

| KEGG | C14186 |

| MeSH | D014261 |

| PubChem CID | 6327 |

| RTECS number | VV7160000 |

| UNII | F82TGU9A8Z |

| UN number | UN1298 |

| Properties | |

| Chemical formula | C3H9ClSi |

| Molar mass | 108.64 g/mol |

| Appearance | Colorless transparent liquid |

| Odor | Sharp, irritating |

| Density | 0.857 g/mL at 25 °C |

| Solubility in water | Decomposes in water |

| log P | 2.7 |

| Vapor pressure | 35 kPa (at 20 °C) |

| Acidity (pKa) | pKa ≈ 8.0 |

| Basicity (pKb) | 13.60 |

| Magnetic susceptibility (χ) | −44.0·10⁻⁶ cm³/mol |

| Refractive index (nD) | nD 1.391 |

| Viscosity | 0.45 mPa·s |

| Dipole moment | 1.05 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 256.7 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -322.3 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -1621 kJ/mol |

| Hazards | |

| GHS labelling | GHS02, GHS05, GHS07 |

| Pictograms | GHS02,GHS05 |

| Signal word | Danger |

| Hazard statements | H226, H301, H311, H314, H331 |

| Precautionary statements | P210, P261, P271, P280, P303+P361+P353, P305+P351+P338, P312, P337+P313, P403+P233 |

| NFPA 704 (fire diamond) | 3-4-2-W |

| Flash point | -28 °C |

| Autoignition temperature | 290 °C |

| Explosive limits | 1.2% - 9.6% |

| Lethal dose or concentration | LD50 oral rat 1620 mg/kg |

| LD50 (median dose) | LD50 (median dose): Oral (rat) 2,296 mg/kg |

| NIOSH | GV6125000 |

| PEL (Permissible) | PEL: 10 ppm |

| IDLH (Immediate danger) | 200 ppm |

| Related compounds | |

| Related compounds |

Methyltrichlorosilane Dimethyldichlorosilane Tetramethylsilane Methyldichlorosilane Chlorotrimethylsilane |